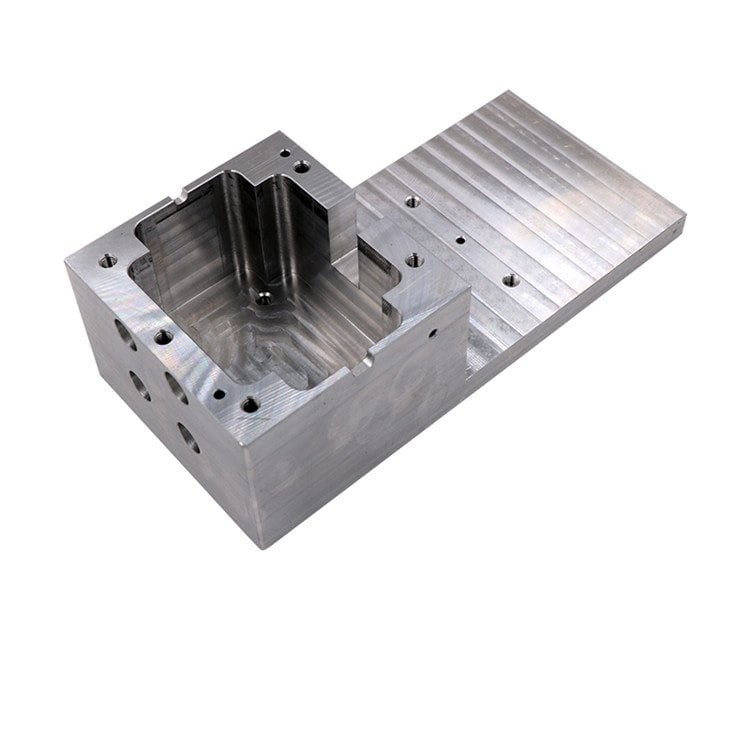

Aluminum alloy In CNC Machining

Provide manufacturing process, metal, and plastic instructions to meet the specific requirements of your CNC machined parts.

Aluminum alloy

Aluminum alloy 6061 Aluminum alloy CNC machining

It is a high quality aluminum alloy produced by heat treatment and pre-stretching process. Although its strength cannot be compared with 2XXX series or 7XXX series, its magnesium and silicon alloy characteristics are many, and it has excellent processing performance, excellent welding characteristics and plating, good corrosion resistance, high toughness and no deformation after processing, dense material without defects and easy polishing, easy color film, excellent oxidation effect and other excellent features. Widely used in decoration, packaging, construction, transportation, electronics, aviation, aerospace, weapons and other industries.

Aluminum alloy 2A12 Aluminum alloy CNC machining

2A12 aluminum alloy is a kind of high-strength hard aluminum, which can be strengthened by heat treatment; 2A12 aluminum alloy has good spot welding weldability, but has the tendency to form intergranular cracks when gas welding and argon arc welding; 2A12 aluminum alloy has good machinability after cold work hardening. Corrosion resistance is not high, often using anodic oxidation treatment and painting methods or surface cladding aluminum layer to improve corrosion resistance. It is mainly used for making various high load parts and components (but not including forgings of stamping parts) such as aircraft skeleton parts, skins, spacer frames, wing ribs, wing beams, rivets and other working parts below 150℃.

Aluminum alloy 6063 Aluminum alloy CNC machining

6063 aluminum alloy is a profile aluminum alloy, which is widely used in the framework of building aluminum doors, windows and curtain walls. In order to ensure that the doors, windows and curtain walls have high wind pressure resistance, assembly performance, corrosion resistance and decorative performance, the requirements for the comprehensive performance of aluminum alloy profiles are much higher than the industrial profile standards.

Why Choose V1 Machining

Our goal is to be your reliable partner. What we are pursuing is a long-term cooperative relationship.

Offering a wide range of parts to be machined, you will receive reports just as if you were in our factory.

16 years experience in machining metal parts

V1 Machining is a ISO9001:2015 and ISO 14001:2015 and IATF 16949 certified company

Advanced equipment and professional testing, experienced engineer team

Digital scientific management to promote efficient operation of teams and suppliers

Leave A Message

Metal Materials For CNC Machined Parts

We have our own strict standards for the materials we process. However, we will also provide materials that meet the standards according to the needs of our customers. In general we often use the following materials.