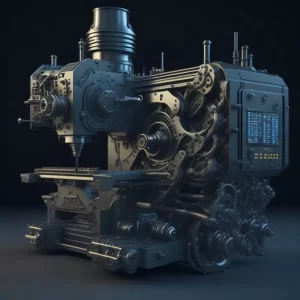

Know about Precision Mold Parts

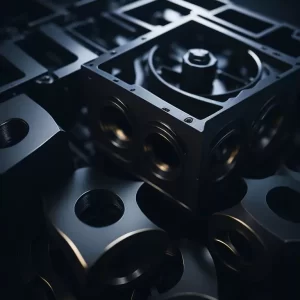

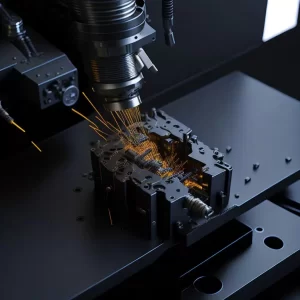

Precision mold parts are unique components that are specifically designed to fit into a mold and help accurately shape and form various materials used in manufacturing. These parts allow manufacturers to create products with high precision, accuracy, and consistency.