Mechanical Parts machining service

- 16 years experience in machining metal parts

- Advanced equipment & professional testing,quality assurance

- Digital management process,amazing efficiency

About Mechanical Parts Machining Manufacturer

Efficient and high quality machining of parts, resulting from a professional and segmented approach to business

For processing orders of mechanical part, all are produced and processed by “Mechanical Parts Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China. As a professional mechanical parts supplier, we can perform CNC machining, milling, turning, and other processes to customize parts.

For the processing and customization of precision mechanical parts, it is mainly carried out by turning and milling compound machining. the mechanical parts supplier has the following characteristics:

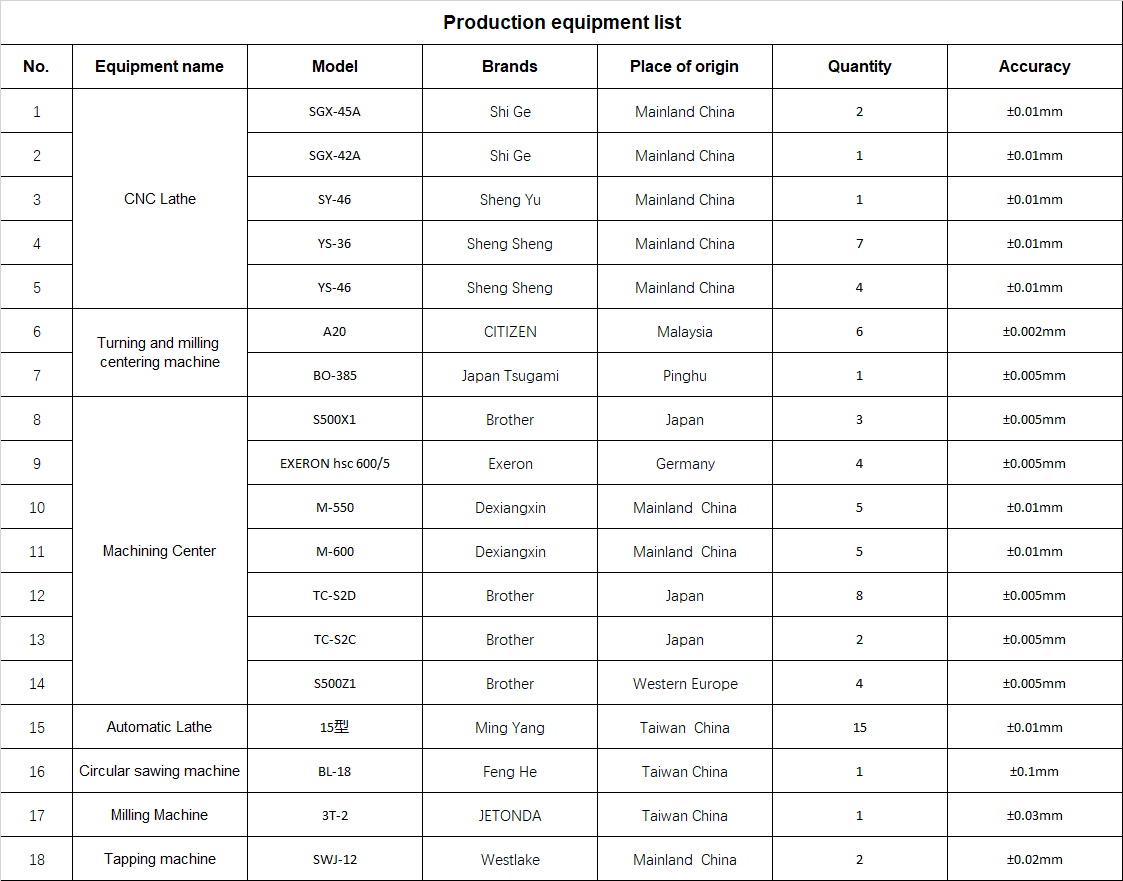

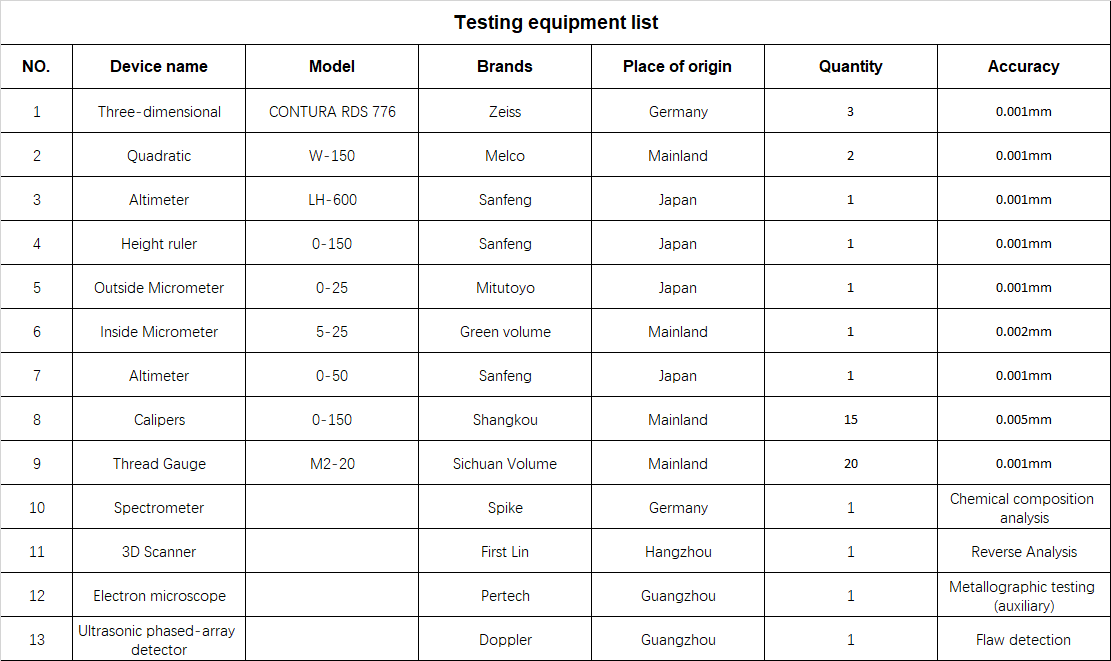

- Has professional production equipment and testing equipment.

- Possess high-quality management systems such as ISO 9001:2015, ISO 14001:2015 and IATF 16949 certification to ensure high-level, high-precision parts.

- Has advanced production management and order follow-up system to ensure that orders are efficiently produced, tracked throughout the process, and delivered on time and with high quality.

Mechanical Parts Machining's Capacity

All 100% real photos are from the Mechanical Parts Machining Manufacturer

Quality Assurance

3-dimensional detection It can accurately detect the size, shape and shape tolerance of the workpiece, so as to complete the tasks such as part inspection, shape measurement, process control and so on.

- Precision

- Accuracy

- Complexity

Our Service Flow

A praiseworthy processing service . that comes from a rigorous service process and the scientific management of a professional team

Strickly according to 3D drawing sheet, and send you 2D drawing before processing. Avoid problems as much as possible

According to the processing requirements of different workpieces, we adopt the most suitable processing flow. Milling, grinding, CNC, EDM, wire-cutting respectively.

Strickly according to drawing sheet tolerance. 3D measure report could be sent before shipment.

All-round protection of packaging materials to ensure the occurrence of bruises during transportation

Deal with it actively and do not shirk its responsibility.

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries: