CNC Cutting Services

V1 Machining is a trusted online CNC services supplier that is able to provide custom cut parts for your project with top quality and fast shipping. With decades of experience and expert capabilities, our CNC cutting services can cut an extensive range of materials using laser cutting, waterjet, and other technologies. According to your requirements and applications, we’ll offer suggestions for the product design, suitable materials, and the most cost-effective methods for CNC cutting and manufacturing. Minimal cost, time and best quality are our purposes. Equipped with state-of-the-art facilities and measuring equipment in our factory, CNC metal and plastic cutting now supply CNC cutting parts for a number of business sectors and private individuals, catering both long and short production runs.

What is CNC Cutting Process?

Unlike traditional cutting services, CNC cutting is a subtractive manufacturing method that uses a variety of different cutting technologies combined with computer numerical control software to remove excess materials from the block and create specific 2D or 3D shapes. Common CNC cutting machines and tools including laser, water jet, route, plasma, knife, etc. CNC cutting services provide products for aerospace, automotive, chemical, agriculture, military, defense, and more commercial and industrial applications. CNC cutting is widely applied due to its speed, precision and accuracy, as well as little human error. CNC cutting process can be performed alone or with other processes depending on the configuration and purposes.

Why Choose V1 CNC Cutting Company

CNC cutting uses Computer Numerical Control devices and specialized tools to produce final parts based on the CAD design or drawing provided by clients.

- Highly trained machinists and skilled engineers can help you create and improve the design.

- A broad range of techniques can be performed at our machine shop with efficiency and speed.

- With up-to-date manufacturing facilities, our CNC machines work with a number of materials.

- Final CNC custom cut parts with high precision are easily reproducible in a much shorter time.

- Prompt reply and communication, we’ll get you updated on the whole progress of the production.

- Free online quotes and design feedback to provide effective solutions and suggestions.

Types of CNC Cutting

CNC Plasma Cutting:

Stainless steel, mild steel, aluminum, brass, etc.

- Ideal for budget rapid prototyping, large pieces, and extended jobs - Most affordable cutting option

CNC Laser Cutting:

Various materials including tough metals and gemstones - Extremely quick process

- Excellent cut edge quality and high level of detail

- Can produce intricate parts to high tolerances with a smooth surface finish

CNC Waterjet Cutting:

Almost any material

- Versatile method to cut almost any material - Good surface quality with no heat affected zone

Note: CNC stands for Computer Numerical Control, which refers to the use of computer software to control the cutting process.

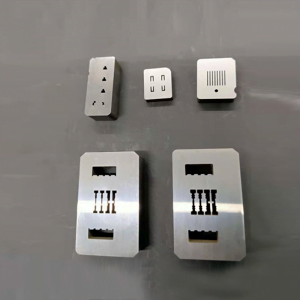

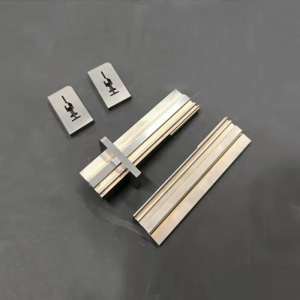

Products

.01

Mechanical Parts Machining's Capacity

For processing orders of mechanical part, all are produced and processed by “Mechanical Parts Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

72

Production equipments

49

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.02

Precision Mold Parts Machining's Capacity

For processing orders of precision mold parts, all are produced and processed by “Precision Mould Parts Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

66

Production equipments

24

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

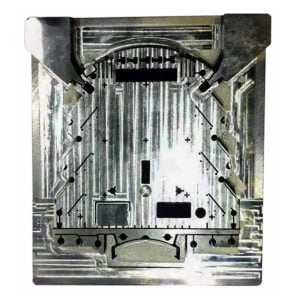

.03

Large Parts Machining's Capacity

For the processing and customized orders of Large parts, the “Large CNC Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

59

Production equipments

154

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

CNC Manufacturing Materials

Choose the right materials for your manufacturing needs from prototype to production

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries:

Custom CNC Cutting Services

If you need any metal and plastic materials CNC Cutting and custom surface treatment services