Industrial Robotics

CNC Machining Parts Solutions

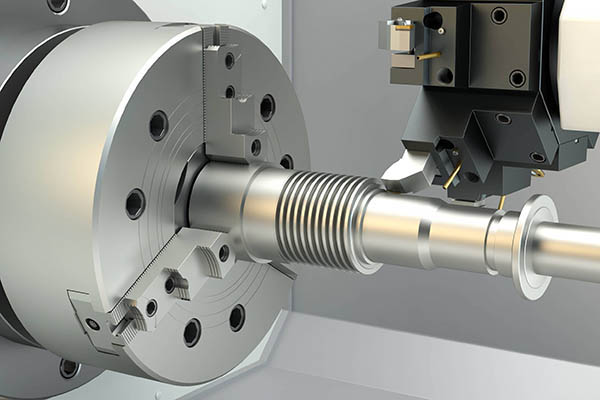

CNC Machining Services For Industrial Robotics Parts

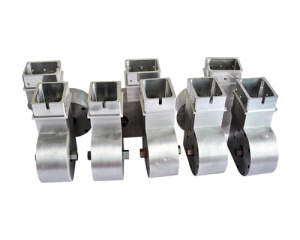

There are many kinds of robot parts with different shapes, and the assembled fit should be very good, which requires a CNC machining robot parts manufacturer who can handle a variety of machining processes and trial assemblies, and special new precision is good at flexible application of a variety of processes, and can customize reasonable and economical machining processes for products and trial assemblies for customers to help customers shorten the product cycle, save development costs and save time and effort. Specialized new precision CNC machining robot parts processing process are: CNC milling machine processing, CNC lathe processing, CNC grinding machine processing, EDM processing, wire cutting processing, etc.

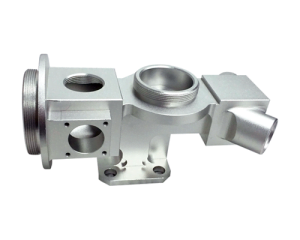

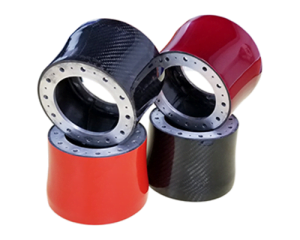

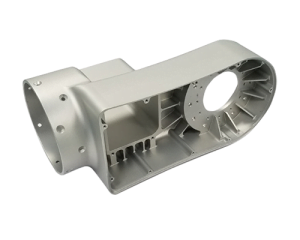

Cases we have done

Industrial Robotics Parts CNC Machining

Manufacturing flexibility - Because cnc machining is computer-controlled, there is tremendous machining flexibility. CNC programs can be easily updated, allowing the machine to perform more complex machining operations

Quality materials - Strict use of raw materials, refusal to cut corners, every product is made with care

Cost reduction - Free optimization and manufacturability optimization, cost reduction through yield, less abnormalities before mass production after sample, fast response to abnormalities.

Good quality rate - 10 quality inspection processes, layers of control, appearance parts straight through rate up to 98%

Powerful capacity - CNC machines run continuously 24 hours a day. In addition, with regular maintenance, these machines can be used for many years for product processing projects.

Fast production - Quickly cooperate with customers to do structure verification and appearance effect verification.

Quality service - timely communication with customers on production progress, 3+1 service, on-time delivery.

Industrial Robotics Parts CNC Machining

Why Choose V1 Machining

Our goal is to be your reliable partner. What we are pursuing is a long-term cooperative relationship.

Offering a wide range of parts to be machined, you will receive reports just as if you were in our factory.

16 years experience in machining metal parts

V1 Machining is a ISO9001:2015 and ISO 14001:2015 and IATF 16949 certified company

Advanced equipment and professional testing, experienced engineer team

Digital scientific management to promote efficient operation of teams and suppliers

Leave A Message

CNC machining automation equipment and robot parts

The use of automation was popularized by the automotive industry in the 1940s to aid in the mass production of vehicles. Today, industrial robots are widely integrated into high-speed manufacturing systems and provide new standards of efficiency. High speeds require the most exacting levels of precision, and our state-of-the-art 3, 4 and 5-axis CNC machining equipment allows for this.

As computer power and precision engineering advance, automation becomes more and more refined, and robots around the world are performing and inspecting extremely complex tasks. At least with the necessary human intervention, cnc machining can run 24/7 with employees keeping everything running. With this constant use, the reliability of the surrounding infrastructure is of paramount importance - and this is where V1 Machining can help.

CNC machining of a wide range of materials

We specialize in precision CNC machining of a wide variety of materials, including wear-resistant mild steel and stainless steel - we also custom machine aluminum, titanium, brass, engineering plastics and more. Wear-resistant materials are particularly well suited for precision machined substrates and long-life components. With over 100 CNC machining centers, and the fact that we regularly hold inventory in a variety of materials, allows us to start your project immediately.

Robot Parts Machining

We can assist in the design and manufacture of base plates, tooling, fixtures and other components to customize parts to your individual requirements. High precision, attention to detail, and high-speed service when needed are guaranteed. We specialize in utilizing 5-axis CNC machining

We offer a one-stop machining service that allows designers and R&D engineers in the automated manufacturing industry to streamline the procurement process - we can source materials, machine parts and perform any additional processes you need, including painting, plating, polishing and more.

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries: