CNC Machining Services

- 16 years experience in machining metal parts

- Advanced equipment & professional testing,quality assurance

- Digital management process,amazing efficiency

- Tolerances down to +-0.001mm

CNC Drilling Services

V1 Machining provides the best CNC drilling services for the fabrication of both small and large series of CNC drilling parts.

- Global delivery as fast as 10 days

- Machined prototypes in as fast as 1 days.

- 50+metals and plastics

- Tolerances down to +-0.05mm

- ISO 9001:2015, CE:SHBST100665461231

What Is CNC Drilling Process

CNC Drilling is primarily done on CNC machines including CNC milling machines and lathes. CNC drilling service produces round holes, typically for machine screws and bolts. Drilling can process CNC drilling parts with metals, hard plastics, wood and most other rigid materials. The step-by-step process for CNC drilling includes:

- The operator uploads and accesses the computer-aided design (CAD) or computer-aided manufacturing (CAM) file.

- The operator installs the appropriate drill bit and secures the designated material on the table.

- The operator starts the drilling process through the control panel or interface.

- The spindle lowers, drilling the appropriate hole sizes and diameters.

CNC Drilling For Precision Parts

V1 Machining provides best CNC drilling services for the fabrication of both small and large series of parts of any complexity. We use various types of CNC drilling machines including upright, bench, radial, which allows us to drill holes of both simple and complex patterns up to 7 cm in diameter. The CNC drilling parts be made of metals and alloys (aluminium, steel, copper and others) and polymers.

Our drilling services provide us with the capability to complete your job in-house to our exacting quality standards. Our advanced CNC drilling equipment is integrated with our machining centers and allows us to efficiently and precisely drill your part, whether you require simple or complex drilling patterns. Our drilling services offer precision machining for complex shapes that meet all your requirements.

CNC Machining Surface Finishes

Along with our CNC machining services, you can opt for a wide selection of metal surface finishing services for your CNC drilling parts to improve the parts appearance, surface smoothness, corrosion resistance and other performance.

| Surface Finishing Method | Description | Materials Applied | Purpose |

|---|---|---|---|

| Painting | Altering surface finishes by spraying paint, pigment, or colour to a solid surface as a coloured protective layer. | Metal or non-metal CNC machined components of any shapes, usually applied on aluminum, stainless steel and steel alloy parts. | To improve aesthetic appearance and prevent corrosion or oxidation. |

| Passivation | A common chemical surface treatment method for steel and stainless steel is to remove ferrous contaminants or use a light coat of protective material to create a shell to enhance the corrosion resistance or reduce the chemical reactivity. | Steel and stainless steel | To enhance corrosion resistance or reduce chemical reactivity. |

| Electroplating/Plating | An electric current is used to reduce dissolved metal cations to form a thin coherent metal coating on an electrode. | Various materials, used to change the properties of the metal surface or build up thickness for undersized parts. | To change the properties of the metal surface or build up thickness for undersized parts. |

| Anodizing/Anodized | An electrolytic passivation process of forming a thin aluminium oxide layer on the exterior of aluminium CNC machined parts. | Aluminum | To increase the thickness of the natural oxide layer and protect the metal, as the layer has higher corrosion and abrasion resistance than aluminum. |

| Black oxide | An electrolytic passivation process of forming a black oxide layer on the exterior of ferrous metal parts. | Ferrous metals such as steel | To improve corrosion resistance and provide a black appearance. |

Products

.01

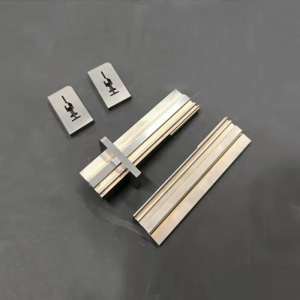

Mechanical Parts Machining's Capacity

For processing orders of mechanical part, all are produced and processed by “Mechanical Parts Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

72

Production equipments

49

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.02

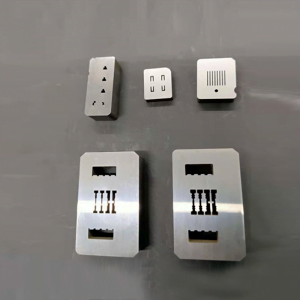

Precision Mold Parts Machining's Capacity

For processing orders of precision mold parts, all are produced and processed by “Precision Mould Parts Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

66

Production equipments

24

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.03

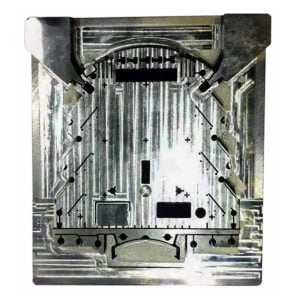

Large Parts Machining's Capacity

For the processing and customized orders of Large parts, the “Large CNC Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

59

Production equipments

154

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

CNC Manufacturing Materials

Choose the right materials for your manufacturing needs from prototype to production

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries:

Custom CNC Drilling Services

If you need any metal and plastic materials CNC Drilling and custom surface treatment services