Consumer Electronics

CNC Machining Parts Solutions

CNC Machining Services For Consumer Electronics

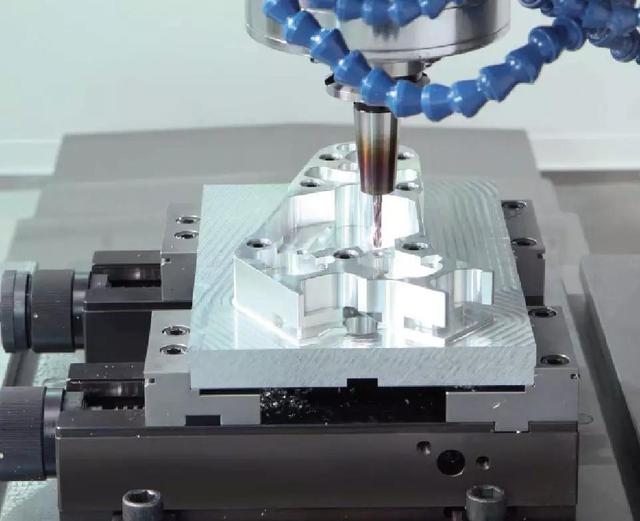

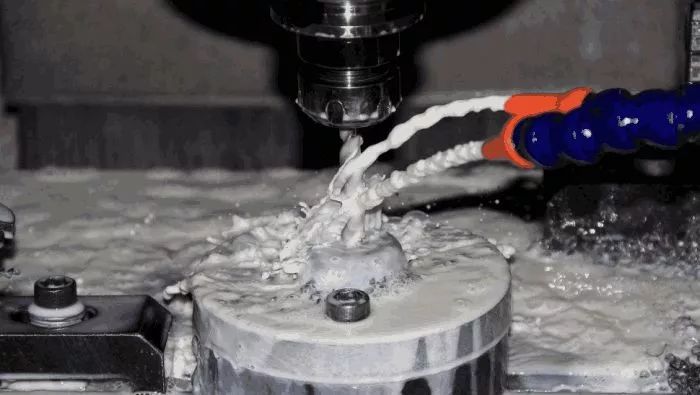

Aluminum alloy shell processing of electronic products in the consumer industry, cnc precision parts production processing manufacturing. According to the customer's non-standard precision hardware parts processing needs, combined with hot and cold forging, die-casting, extrusion, CNC turning and milling processing and a variety of difficult surface treatment processes, etc., to provide customers with low-cost high-quality integrated solutions.

Cases we have done

Consumer Electronics Parts CNC Machining

Experience: 13 years of experience in CNC machining of aluminum alloy shells for brand owners with high demand for exterior parts

Team:3 process engineers with more than 20 years of experience in the engineering department. 9 programming engineers with more than 20 years of experience in the CNC machining centre department.

CNC machining tolerances: Our standard tolerances for CNC machining of aluminium alloys are DIN-2768-1-fine and for plastics DIN-2768-1-medium. tolerances are strongly influenced by part geometry and material type. For case studies, please contact us for detailed information.

Machining processes: CNC machining of aluminium alloys, housing for electronic products, CNC lathe machining, 5-axis machining, automatic lathe machining, surface grinding, etc.

CNC machining: aluminum alloy casing machining, aluminum profile machining, cnc parts machining 16 years rich cnc machining custom experience manufacturers. Aluminum cnc machining products are widely used in electronic products industry.

Consumer Electronics Parts

Why Choose V1 Machining

Our goal is to be your reliable partner. What we are pursuing is a long-term cooperative relationship.

Offering a wide range of parts to be machined, you will receive reports just as if you were in our factory.

16 years experience in machining metal parts

V1 Machining is a ISO9001:2015 and ISO 14001:2015 and IATF 16949 certified company

Advanced equipment and professional testing, experienced engineer team

Digital scientific management to promote efficient operation of teams and suppliers

Leave A Message

What is the difference between CNC machining of aluminium housings and die-casting?

The production of electronic products aluminum shell usually need to find a professional formal aluminum shell manufacturer for processing custom, because different brands and models of products for aluminum shell requirements are different, specifically in shape, size and appearance processing, and contact with aluminum shell processing people will know that there are two processing technology in the industry, that is, CNC processing and die-casting processing, both are the raw materials Processing into the expected product technology, but many people are not very understanding of the two, the following V1 Machining briefly share the difference between CNC machining and die-casting processing of aluminium housings.

Processing methods are different.

CNC processing is index-controlled processing, is under the digital control of the computer precision mechanical processing, aluminum shell in this processing process can achieve some extremely special or complex surface treatment, such as bevel cutting, non-penetrating pattern or texture engraving, aluminum shell bending at the hole treatment, non-flat surface treatment.

Die casting is the process of applying high pressure to molten metal using the cavity of the mould to create a surface similar to that of the mould.

Differences in processing difficulty.

CNC machining can say that even the most demanding and difficult details can be accomplished with CNC machining processing.

Die casting allows for some simple punching and pattern forming work, which is less costly than CNC machining, but does not allow for very complex surface finishes.

As you can see, if you want to produce a qualified aluminium housing, you need to choose the appropriate process according to its production needs. At the same time, we also have to take into account the cost of production, in the case of both processing processes are feasible, naturally, which one is more convenient and more beneficial to choose which one, rather than that which looks better to choose which one, after all, the actual actual needs of their own is also very important.

Partner with V1 Machining for better quality parts

with the help of CNC hand-forming technology, automotive manufacturers can produce high fidelity components with the optimum capacity offered by the system. The automotive industry requires tolerances of ±0.001" due to the type of products it offers to consumers.

CNC machining offers faster production times. This is due to its automated nature, eliminating the need for lengthy and labour-intensive manual machining.

design and produce any complex CNC medical part from customer drawings and samples

Being a computer controlled process, automotive CNC machining also brings the assurance of repeatability. This is a key element in any industrial grade production environment. In the automotive industry, it is vital to ensure consistent part batches. In this way, all CNC vehicles launched will meet the same standards.

nearly 100 CNC machines can withstand high volume production

providing a reliable and fast solution for auto parts handpieces

timely communication with customers on production progress and on-time delivery

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries: