Large Die In Mold Industry

CNC Machining Parts Solutions

CNC Machining Services For Mold Parts

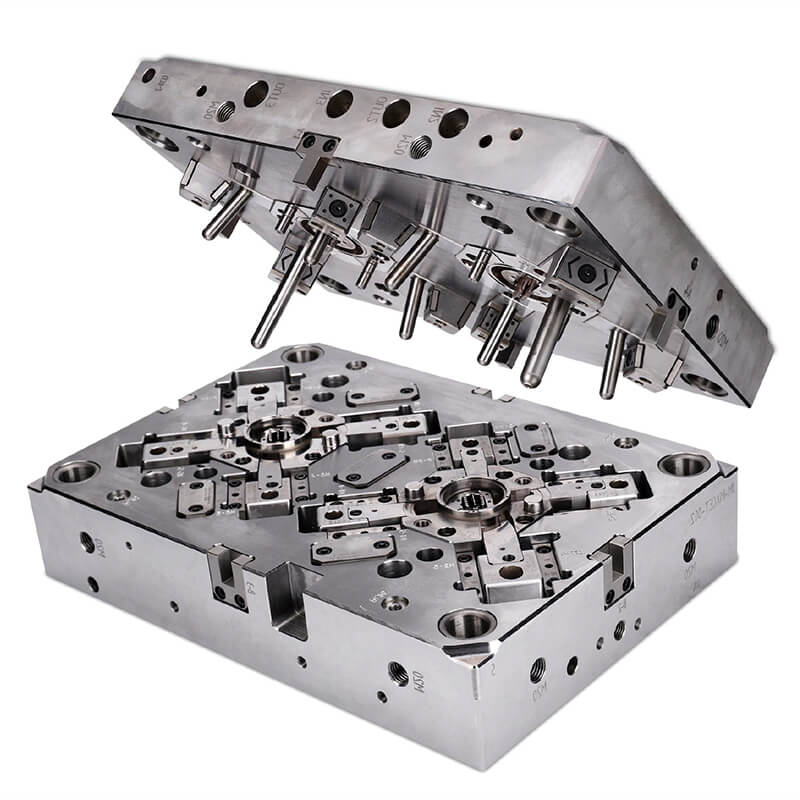

Mold manufacturing is an extremely complex and precise process, and the accuracy of the mold directly determines the accuracy of the product. V1 Machining provides mold companies with a full range of mold part machining services, such as die kernels, cores, inserts, beveled tops, sliders, etc., ensuring that the accuracy and quality of the parts meet your requirements.

Cases we have done

Large Die Parts CNC Machining

Efficient and high quality machining of parts, resulting from a professional and segmented approach to business

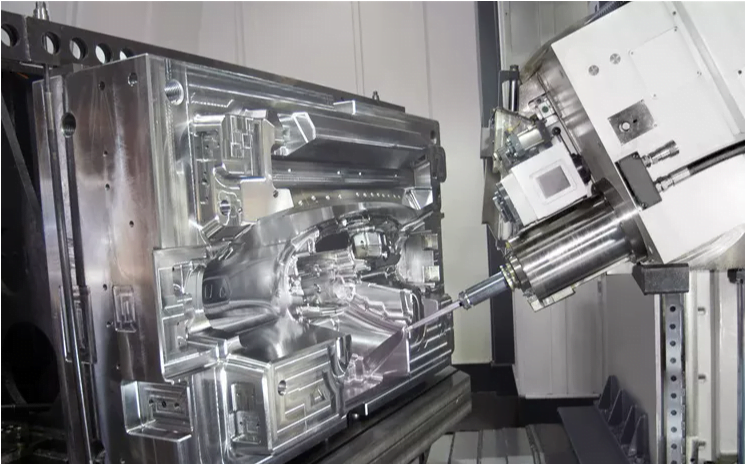

For the processing and customized orders of Large Die parts,all are produced and processed by the “Large CNC Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China. For the processing customization of Large Mold Parts, the Large CNC Machining Manufacturer has the following characteristics:

- Has professional production equipment and testing equipment.

- Possess high-quality management systems such as ISO 9001:2015, ISO 14001:2015 and IATF 16949 certification to ensure high-level, high-precision parts.

- Has advanced production management and order follow-up system to ensure that orders are efficiently produced, tracked throughout the process, and delivered on time and with high quality.

Large Die Parts Cases

About Precision Mold Parts CNC Machining

Precision moulds are mainly used in electronics, medical, robotics, automated mechanical equipment and other fields. The requirements for precision mould parts are high precision and small size, which requires that when processing precision mould parts, there are not only strict requirements for materials, but also need to make full use of the performance of the equipment and design different processing processes in order to produce high precision and high quality mould parts with high efficiency and low cost, therefore, V1machining has set up a special branch factory for precision mould parts processing responsible for production, more ......

Why Choose V1 Machining

Our goal is to be your reliable partner. What we are pursuing is a long-term cooperative relationship.

Offering a wide range of parts to be machined, you will receive reports just as if you were in our factory.

16 years experience in machining metal parts

V1 Machining is a ISO9001:2015 and ISO 14001:2015 and IATF 16949 certified company

Advanced equipment and professional testing, experienced engineer team

Digital scientific management to promote efficient operation of teams and suppliers

Leave A Message

Key Points Of CNC Machining In The Mold Parts Industry

The machining of moulded parts is adapted to different moulded parts, different materials, different shapes and different technical requirements. There are many selective solutions available and V1 Machining's experienced engineers are able to provide customers with professional solutions for the machining of moulded parts. V1 Machining classifies mould parts into three categories based on their appearance and shape: shafts, discs, plates and formed shaped parts. The production of moulded parts requires attention to the following points.

Heat treatment for CNC machining of mold parts

In order to obtain the required heat treatment hardness of mold parts, the internal stress of the parts heat treatment must be controlled so that the tolerance of the parts can be stabilized. There are different heat treatment methods for parts made of different materials, and V1 Machining has mature processing experience in heat treatment of different CNC machined parts.

CNC machining grinding process for mold parts

There are three types of machine tools used for grinding processing: surface grinder, internal and external cylindrical grinder and tool forming grinder. For fine grinding, in order to strictly control the emergence of grinding deformation and grinding cracks, the tool feed should be small during fine grinding, the cooling should be adequate during grinding, and the coolant medium should be chosen as much as possible, and for parts with machining allowance within 0.01mm, constant temperature grinding should be used as much as possible. Most of the disc and plate parts are processed by surface grinder, while the shaft parts are characterized by multiple rotary surfaces and are generally ground by internal and external cylindrical grinder.

Electro-machining of mold parts

Electric machining can effectively process various types of shaped, various types of cavities or high hardness parts, and has become an essential processing means for the mold manufacturing and metal processing industry. Using slow-walking wire cutting processing technology, the accuracy can reach ± 0.002mm, roughness Ra = 0.4μm. for high-precision workpiece, to ensure the quality of the parts commonly used four cuts, EDM surface than ordinary mechanical processing or heat treatment of the surface is more difficult to grind, so the EDM process should be used before the end of the fine machine number dressing to remove the surface formed by the hardened thin layer.

CNC machining surface treatment of mold parts

There are three types of machine tools used for grinding processing: surface grinder, internal and external cylindrical grinder and tool forming grinder. For fine grinding, in order to strictly control the emergence of grinding deformation and grinding cracks, the tool feed should be small during fine grinding, the cooling should be adequate during grinding, and the coolant medium should be chosen as much as possible, and for parts with machining allowance within 0.01mm, constant temperature grinding should be used as much as possible. Most of the disc and plate parts are processed by surface grinder, while the shaft parts are characterized by multiple rotary surfaces and are generally ground by internal and external cylindrical grinder.

Our Amazing Clients

The satisfaction of each customer ,The highest standard of our service.

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries: