Production Capability

V1 Machining's 3 sub-factories

V1 Machining as a quality China CNC machining supplier & manufacturer has a strong production capacity. Not only because of the 16 years of development history. At the same time, we are constantly updating our production facilities, but more importantly, we are constantly aware of the importance of specialization in our business during our development.

Efficient And High Quality Machining Of Parts, Resulting From A Professional And Segmented Approach To Business

As a result, we have set up three specialised sub-factories for the production and machining of large parts, precision parts, shafts and disc parts which require different equipment and machining processes, for mechanical parts, precision moulded parts and large moulded parts respectively. With this organisational structure, human resources are fully utilised and equipment is effectively utilised, enabling us to provide an efficient and high quality parts machining service.

Understanding the production capabilities of V1 Machining's 3 sub-factories will enable you to make a quicker decision on whether to choose us.

.01

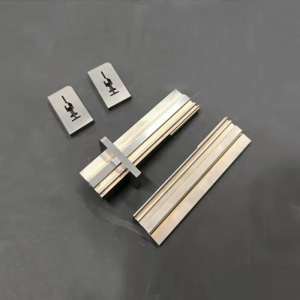

Mechanical Parts Machining's Capacity

As a china cnc machining manufacturer for processing orders of mechanical part, all are produced and processed by “Mechanical Parts Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

72

Production equipments

49

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

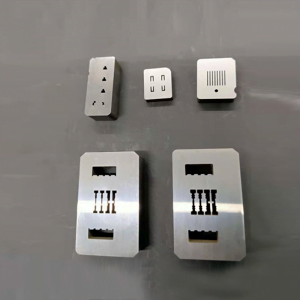

.02

Precision Mold Parts Machining's Capacity

About processing orders of precision mold parts, all are produced and processed by “Precision Mould Parts Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

66

Production equipments

24

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

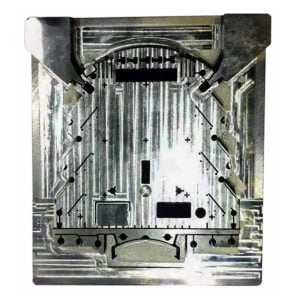

.03

Large Part Machining's Capacity

For the processing and customized orders of Large parts, the “Large CNC Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

59

Production equipments

154

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006