Table of Contents:

- Introduction to Brass CNC Machining

- Best Practices for Brass CNC Machining

- Challenges in Brass CNC Machining

- Future Trends in Brass CNC Machining

- Innovations in Brass Machining

- Conclusion

-

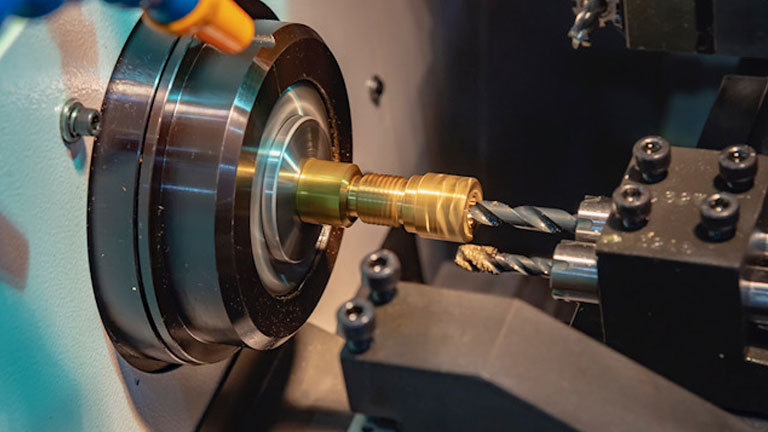

1.Introduction to Brass CNC Machining

Brass CNC machining involves using computer numerical control (CNC) to machine brass into custom shapes and designs. Brass is an alloy made of copper and zinc and is a popular material in industries that require corrosion resistance, high electrical conductivity, and heat resistance.

Benefits of Brass Machining include:

- Corrosion resistance: Brass is highly resistant to corrosion, making it ideal for use in marine and automotive applications.

- Machinability: Brass is easy to machine and can quickly produce complex shapes, reducing production time and costs.

- Electrical conductivity: Brass has excellent electrical conductivity, making it a popular material in electrical and electronic applications.

- Heat resistance: Brass has high thermal conductivity and can withstand high temperatures, making it suitable for use in heat exchangers, fixtures, and fittings.

CNC machining offers several benefits in brass manufacturing, including greater precision and speed, reduced waste, and consistent quality.

-

2.Best Practices for Brass CNC Machining

To achieve optimal performance and quality in brass CNC machining, it is essential to follow best practices. Some of the best practices for brass CNC machining include:

- Choosing the right cutting parameters: This involves selecting the appropriate cutting speed, feed rate, and cutting depth based on the brass grade, the tool being used, and the required finish. Selecting the right cutting parameters ensures optimal performance, improved quality, and reduced tool wear.

- Proper maintenance of cutting tools: Regular maintenance of cutting tools is vital for their effective operation. This includes proper blade or bit sharpening, correct tool alignment, and timely replacement of worn tools to achieve optimal machining results.

- Evaluating the suitability of brass grades: Not all brass grades are created equal, and it is essential to evaluate the properties of different grades and select the most suitable grade for the given application. The grade’s properties, such as hardness, machinability, and resistance to corrosion and wear, should be considered when selecting the right grade.

- Ensuring proper tool path generation: The tool path is the path the cutting tool follows to cut the brass. Generating an efficient tool path involves selecting the right software, programming the machine for the ideal path, and performing simulations to ensure proper cutting parameters and technique.

- Choose the V1 Machining:Provide manufacturing process, metal, and plastic instructions to meet the specific requirements of your CNC machined parts.

By following these best practices, manufacturers can optimize production efficiency, reduce errors, improve quality, and increase productivity in brass CNC machining.

-

3.Challenges in Brass CNC Machining

Although brass is an excellent material for CNC machining, it presents several challenges. Some of the challenges in brass CNC machining include:

- Issues with Chip Control: Brass chips can be small and difficult to control, resulting in potential damage to the workpiece and tools, as well as decreased cutting efficiency.

- Challenges with Heat Management: Due to its thermal conductivity, brass can generate heat during machining, causing thermal expansion, workpiece deformation, and reduced machining accuracy.

- Surface Finish Concerns: Brass is a soft metal that can be prone to scratching, scuffing and other surface marks while being machined. These surface flaws can reduce the quality of the final product.

- Selection of Lubricants and Coolants: Selecting the right lubricating and cooling options for brass machining is critical. Incorrect application of these fluids can cause discoloration and surface oxidation that negatively impacts the aesthetics and performance of the final product.

By understanding these challenges and adapting to the proper techniques, manufacturers can improve their brass machining processes and optimize CNC machining results.

-

4.Future Trends in Brass CNC Machining

The future of brass CNC machining is promising, with advancements in technology and new trends emerging. Some of the future trends in brass CNC machining include:

- Advancements in material research and development: Research into new materials and alloys will continue to improve the properties of brass and expand its range of applications. New alloys with improved wear resistance and hardness will increase the ability to machine complex shapes and designs with greater accuracy.

- Integration with Industry 4.0 technologies: The integration of Industry 4.0 technologies to brass CNC machining could lead to real-time monitoring, optimization, and predictive maintenance. These technologies can gather data that will help improve performance, prevent downtime, reduce errors, and increase efficiency.

- Automation and robotic integration: The demand for faster and more efficient production is driving more companies to integrate automation and robotic systems into their CNC machining operations. The use of Robotics and Artificial Intelligence will lead to more precision, accurate and consistent quality, speed and reduced labor costs.

As these trends continue to be developed and implemented, the future of CNC machining will continue to provide higher efficiency, accuracy, and quality in the production of brass parts and products. By keeping up with emerging trends, manufacturers can stay competitive and meet the demands of the ever-evolving brass CNC machining industry.

-

5.Innovations in Brass Machining

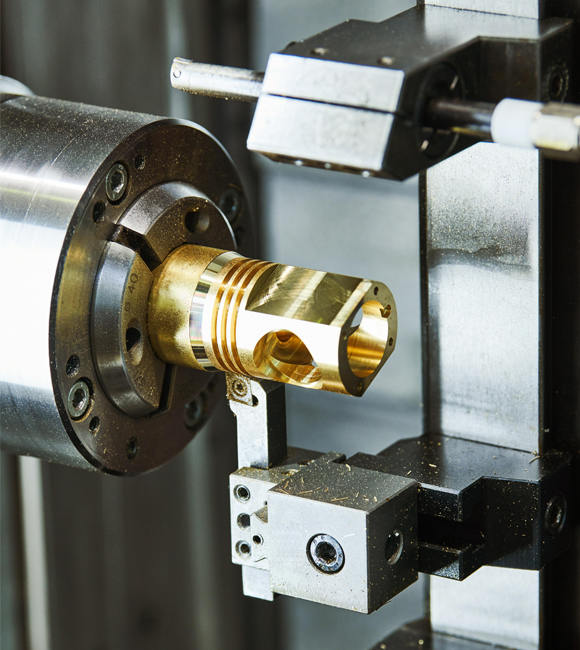

Innovations in brass machining are continually evolving, leading to new advancements in manufacturing technology. Here are some of the latest innovations in brass machining:

- High-speed brass machining: High-speed machining allows for faster cutting speeds, reduced machining time, and higher levels of precision. High-speed machining of brass results in a better surface finish and tighter tolerances, leading to higher quality parts and products.

- Cutting tool materials and design: New materials and designs for cutting tools offer better wear resistance, increased tool life, and improved cutting speeds. These cutting tools include carbide inserts, diamond coated tools, and coated tools.

- Advanced manufacturing technologies: Advanced technologies, such as additive manufacturing, 3D printing, and laser machining, offer new ways to machine brass. These technologies provide greater flexibility in manufacturing, allowing for the production of more complex parts and products and reducing manufacturing times and costs.

By adopting new innovations in brass machining, manufacturers can improve their processes, productivity, and quality control. These advancements in technology also present opportunities for companies to differentiate themselves from their competitors and offer unique solutions to their customers.

-

6.Conclusion

Brass CNC machining is a critical process for various industries. It offers several benefits such as corrosion resistance, high electrical conductivity, and heat resistance. CNC machining of brass presents several challenges such as issues with chip control, challenges with heat management, surface finish concerns, and selection of lubricants and coolants. However, following best practices such as choosing the right cutting parameters, proper maintenance of cutting tools, evaluating the suitability of brass grades, and ensuring proper tool path generation can minimize these challenges.

The future of brass CNC machining is bright, with advancements in material research and development, integration with Industry 4.0 technologies, and automation and robotic integration. High-speed brass machining, cutting tool materials and design, and advanced manufacturing technologies like additive manufacturing and laser machining are continuing to emerge as important innovations in brass machining.

By embracing these emerging trends and technological advancements, manufacturers can improve their production efficiency, reduce errors, improve product quality, and increase productivity in brass CNC machining. The significance of brass CNC machining lies in its ability to offer high-quality parts and products with excellent strength, durability, and corrosion resistance.