At present, the rapid development of social economy puts forward higher requirements for modern machinery manufacturing, and the traditional machinery manufacturing process has not been able to meet the new needs, which requires the active introduction of modern machinery manufacturing process and precision machining technology, so as to promote the rapid and steady development of machinery manufacturing industry.

1. Modern mechanical manufacturing technology

(1) Gas shielded welding technology. Gas shielded welding technology is a kind of welding technology which takes arc as heat source and gas as the protective medium of the welded object. In the welding process, the gas will use its own function to form a strong protective layer around the arc, which can play the role of melting pool and split the arc and air, so as to reduce the harm caused by harmful gas to welding. In addition, it can also make the arc stable and full combustion. More typical carbon dioxide welding.

(2) Stud welding welding process. The stud welding process ensures that one end of the stud is in contact with the surface of the pipe or plate until the contact surface melts, increasing the pressure of the stud to complete the welding. The main welding methods include arc - pulling and energy storage. Both of them are single-sided welding, in which the draw-arc type is mostly used in heavy industry welding, and the energy storage type is mostly used in thin plate welding. The welding process in the use of air leakage and water leakage phenomenon, so it has been widely used. Analysis of modern machinery manufacturing technology and precision machining technology

3) Friction stir welding welding process. Friction stir welding welding technology was first used in vehicle manufacturing, aircraft manufacturing, railway manufacturing and many other machinery manufacturing industries, and with the development of economy, its application scope is increasing. At present, friction stir welding technology in our country is very mature, in the welding process will produce less consumable materials, has greater practicality. And in the welding process of aluminum alloy, 800m welding seam can be directly welded, and the welding temperature is also low.

(4) resistance welding welding process. Resistance welding welding process is placed between the positive and negative electrodes to be welded object, and the implementation of electricity, through the current contact with the surface of the welded object and nearby generated resistance heat effect and melt, promote its integration with the metal. Resistance welding welding process has many advantages, such as high production efficiency, high degree of mechanization, high welding quality, short heating time, so it is widely used in aerospace, automotive, household appliances and other modern machinery manufacturing industry.

(5) Submerged arc welding welding process. Submerged arc welding process refers to welding by burning arc under the flux layer, which can be automatic or semi-automatic. Automatic submerged arc welding is usually only used for welding, while the wire and moving arc need special trolley to transport. However, in semi-automatic submerged arc welding, welding wire and moving arc often need to be delivered manually, so they are almost eliminated in the process of development. In addition, when choosing submerged arc welding technology, special attention should be paid to the selection of flux, alkalinity and other important technical standards that can best reflect welding process performance, metallurgical performance and current class.

The connection and characteristics of modern machinery manufacturing technology and precision machining technology

(1) The correlation between modern machinery manufacturing technology and precision machining technology. In terms of manufacturing technology, modern machinery manufacturing technology and precision machining technology are involved in many aspects of the machinery industry, such as manufacturing engineering, product design and development, product process design, processing and manufacturing, product sales, etc.

Once problems occur in these links, they will directly affect the whole engineering chain. Therefore, we must attach great importance to the correlation between modern machinery manufacturing industry and precision machining technology, so as to truly promote the progress and development of mechanical technology.

Therefore, in concrete practice, we must fully combine modern mechanical technology and precision machining technology to promote mechanical progress and realize the rapid development and progress of technology.

The systematization of modern machinery manufacturing technology and precision machining technology.

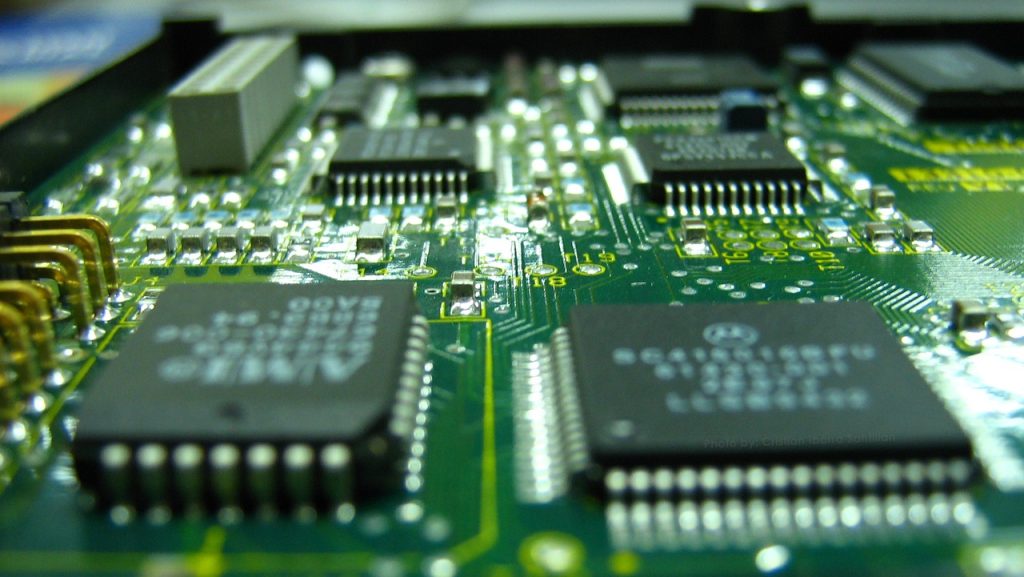

Modern machinery manufacturing production is a relatively complex system engineering, in the use of modern machinery manufacturing process and precision machining technology, such as product design, production and sales process, will involve computer information technology, modern sensing technology, production automation technology and many other technologies. In addition, there may be a need to apply new processes, new materials, new management methods, etc.

Therefore, on the whole, the manufacturing technology of the machinery industry is inseparable from the comprehensive application of a variety of modern advanced science and technology, which makes the modern machinery manufacturing process and precision machining technology has a larger system.