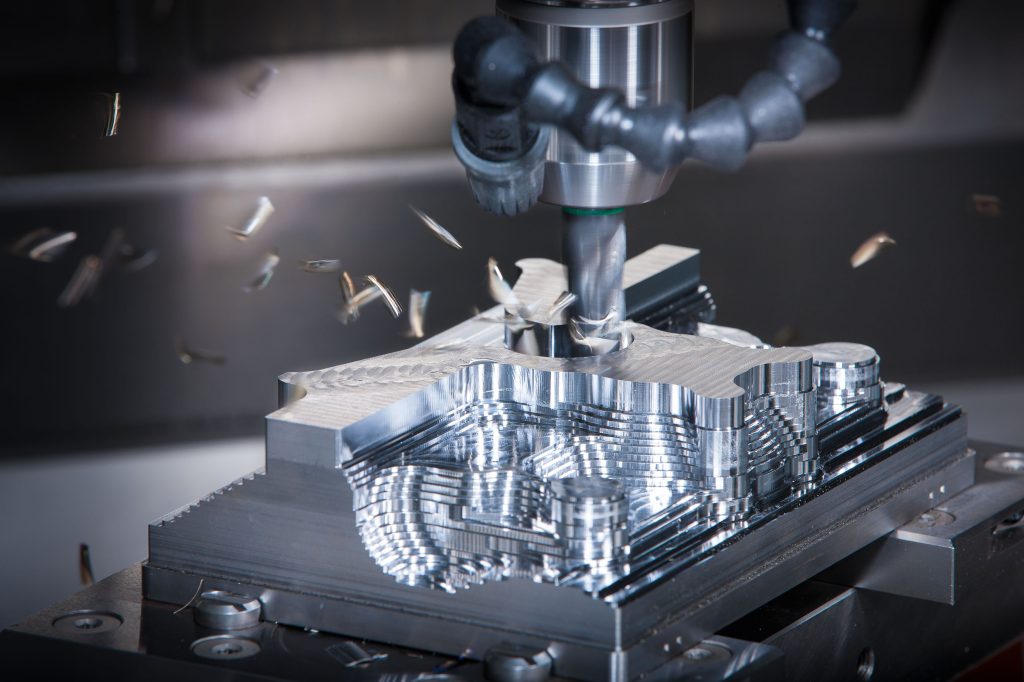

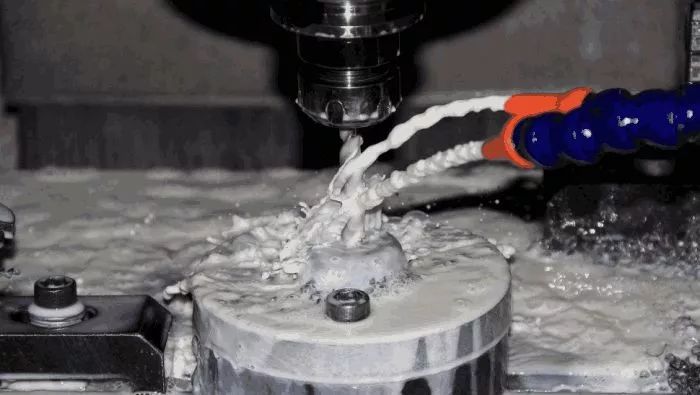

CNC Milling: Everything You Need to Know

CNC milling is a form of computer numerical controlled machining that uses rotating cutting tools to shape and cut materials into precise shapes and sizes. It is a highly accurate and efficient manufacturing process that has revolutionized the production industry.

CNC Milling: Everything You Need to Know Read More »