An Overview of CNC Turning: Techniques and Applications

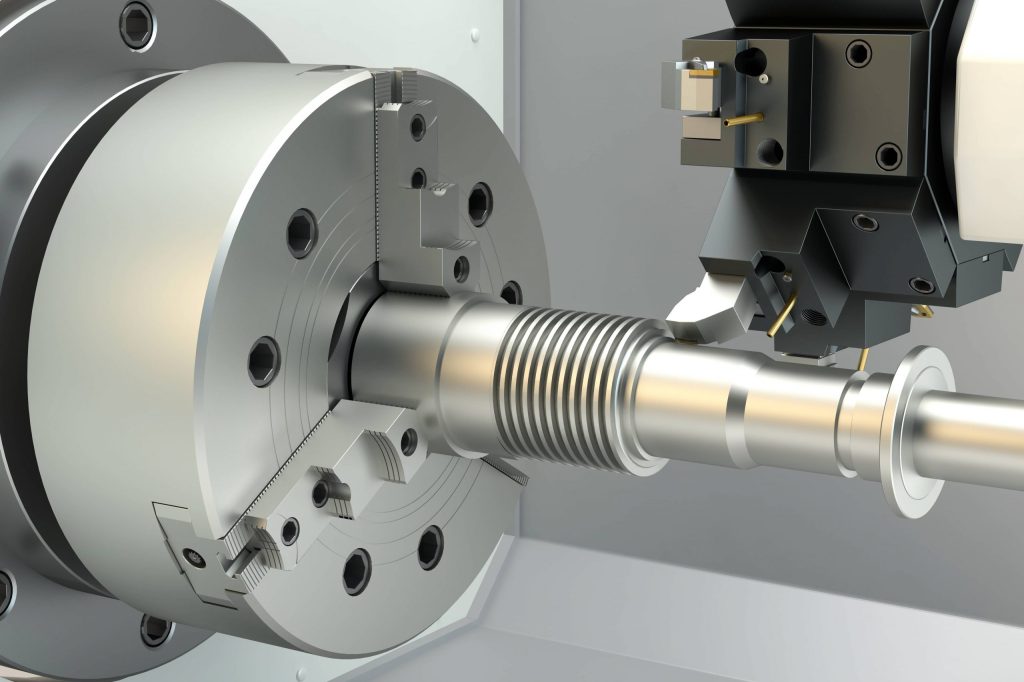

CNC turning, also known as computer numerical control turning, is a manufacturing process that involves the use of computer-controlled lathes to produce parts and components. In this process, a computer program is used to direct the movement of the cutting tool and produce a desired shape or geometry.

An Overview of CNC Turning: Techniques and Applications Read More »