With advances in technology and a revolution in engineering and machinery, you want to know that you are using the best equipment and leading the way for your business. Some of these advances are computer numerically controlled (CNC) machining and 3D printing. They both use different materials.

CNC machining and 3D printing have similarities and differences, each with unique benefits. They have different situations where you may wish to use them in terms of cost and availability. Breaking down each style of manufacturing will help you choose the best method for you and your business.

The main differences between them are production, scrap, scale, material availability and part size.

Similarities between CNC machining and 3D printing

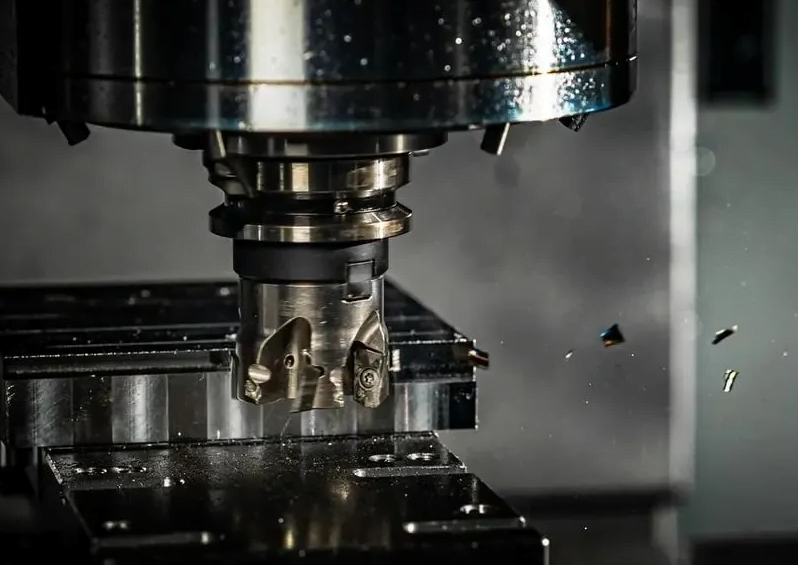

CNC machining and additive manufacturing are both computer-controlled solutions that allow products to be made from specific materials. They are both machines that build technological frontiers safely and efficiently.

When machinists and engineers want to build prototypes, parts or custom products, they can turn to one of these machines to get the job done for them. As long as the machine has a design, you don't have to worry about human error because the machine is automated. While this doesn't mean that problems won't occur, there is greater consistency with production and less chance of injury.

There is some overlap between these two manufacturing methods. Some CNC machines can use STL and OBJ files, which are also accepted by 3D printers.

CNC machines are older than 3D printing and still have a stronger foothold in manufacturing. The form began in the 1940s and has so far been shaped to suit the industry. 3D printing emerged in 1986. It is still relatively new and is constantly evolving to be more accessible and versatile. 3D printing can help in certain areas of prototyping, but it is not a replacement tool for CNC machining.

They are not another alternative, as they are both aspects of manufacturing. They meet different needs and deal with different materials and markets. Both CNC machines and 3D printing have unique features and constraints that suit specific jobs. As they fit into niches in the market, you need to compare them to the industry you are in.

The difference between cnc CNC machining and 3D printing

From the way they are built to the applications they can handle, CNC machining and 3D printing offer creative solutions in a variety of different ways. Identifying their differences and advantages will help you find the right product for you and your business.

3D printers are often more efficient than traditional manufacturing. Printers use the materials that make up the item they are creating, whereas traditional manufacturing methods (such as CNC machining) require more material to make a mould work. On average, 3D printers produce less waste than traditional manufacturing methods.

However, when production is on a larger scale, traditional manufacturing methods have a distinct advantage. Because the printer builds layer by layer, assembly lines are faster than 3D printers in mass production. In the time it takes to 3D print a product, an assembly line can mass produce hundreds of identical products.

In addition, 3D printers can only use the area of the print bed to make parts. Large parts may not fit in that space. While it is possible to break these parts down into smaller parts that can be built by the 3D printer, this may not be cost effective and takes time. Traditional manufacturing has the advantage of assembly line labour and the ability to produce items on a larger scale. Future 3D printers can make larger products, but not in the quality and quantity that CNC machines can offer.

3D printers can manipulate different materials, such as plastics, metals and polymers. However.

Not all 3D printers can work with these materials. Each material requires a separate machine.

Due to the high melting point, 3D printers cannot use all the materials used by traditional manufacturers.

If certain projects require specific materials that are not compatible with the printer, it may not be possible to consider using a 3D printer.

This is the bottom line - 3D printing will not replace traditional manufacturing because of its drawbacks in mass-produced products.