Table of Contents:

- Introduction to Aluminum Alloys

- Types of Aluminum Alloys

- Properties of Aluminum Alloys

- Applications of Aluminum Alloys

- Advancements in Aluminum Alloy Technology

- Aluminum Recycling and Sustainability

- Conclusion: The Future of Aluminum Alloys

-

1.Introduction to Aluminum Alloys

Aluminum alloys are a type of metal alloy composed primarily of aluminum, along with other elements such as copper, zinc, magnesium, and silicon. These alloys are highly versatile, lightweight, and corrosion-resistant, making them ideal for a wide range of applications across various industries.

1.1 What are Aluminum Alloys?

Aluminum alloys are created by combining pure aluminum with other elements, resulting in a material with improved mechanical properties such as strength, hardness, and durability. The resulting alloys are used in the manufacture of a wide range of products, including aircraft parts, automotive components, building materials, and consumer goods.

1.2 History and Development of Aluminum Alloys

The use of aluminum alloys dates back to the early 20th century, when the Wright brothers used aluminum to build their first aircraft. Since then, aluminum alloys have become increasingly prevalent in the aerospace industry, as well as in the automotive, construction, and packaging industries.

Advancements in technology and manufacturing processes have led to the development of new and improved aluminum alloys, with enhanced mechanical and physical properties.

1.3 Properties of Aluminum Alloys

Aluminum alloys are known for their unique combination of properties, including high strength-to-weight ratio, corrosion resistance, thermal conductivity, and electrical conductivity. The properties of aluminum alloys can be tailored to specific applications by adjusting the alloy composition, microstructure, and processing methods.

Overall, the properties of aluminum alloys make them highly versatile and well-suited for a wide range of applications across various industries.

-

2.Types of Aluminum Alloys

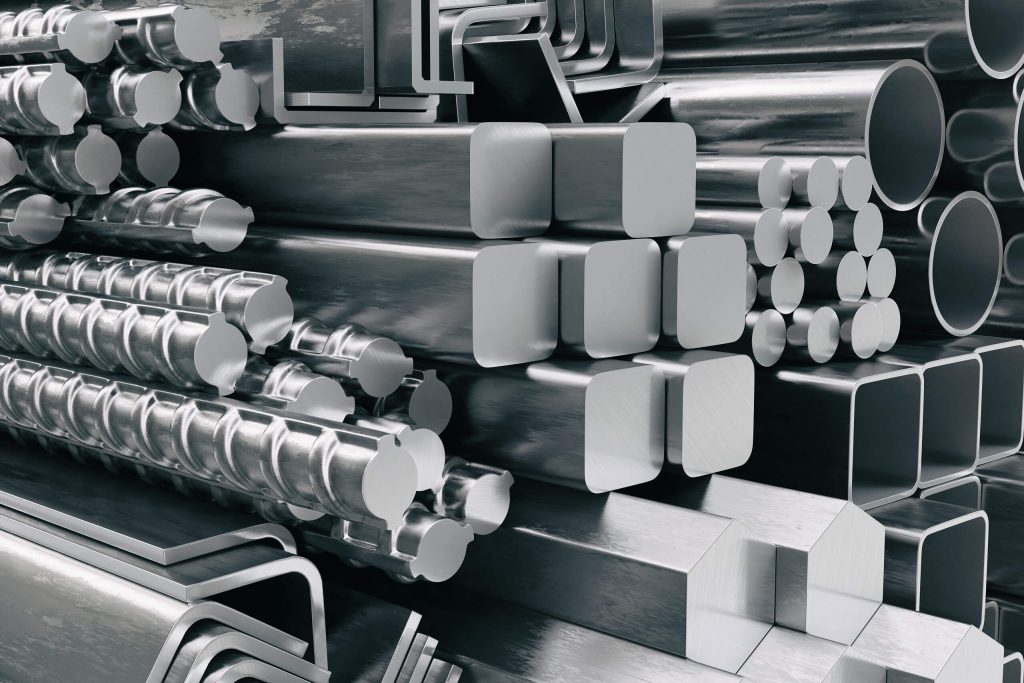

Aluminum alloys can be broadly categorized into three types: wrought aluminum alloys, cast aluminum alloys, and specialty aluminum alloys.

2.1 Wrought Aluminum Alloys

Wrought aluminum alloys are those that are shaped by rolling, forging, or extrusion processes. These alloys are known for their high strength-to-weight ratio and are commonly used in the aerospace, automotive, and construction industries. Wrought aluminum alloys are further classified into two categories:

- Heat-treatable alloys: These alloys can be strengthened by heat treatment, resulting in improved mechanical properties.

- Non-heat-treatable alloys: These alloys are not strengthened by heat treatment, but can be strengthened through cold working processes such as rolling or drawing.

2.2 Cast Aluminum Alloys

Cast aluminum alloys are those that are shaped through the casting process, which involves pouring molten aluminum into a mold and allowing it to solidify. Cast aluminum alloys are known for their excellent casting properties and are commonly used in automotive, aerospace, and consumer goods industries. Cast aluminum alloys are further classified into two categories:

- Aluminum-silicon alloys: These alloys have high fluidity and are used in the manufacture of automotive parts and engine blocks.

- Aluminum-copper alloys: These alloys have high strength and are used in the manufacture of aircraft components and marine applications.

2.3 Specialty Aluminum Alloys

Specialty aluminum alloys are those that are designed for specific applications, such as high-performance racing cars, electrical conductors, and heat sinks. These alloys are typically composed of high-purity aluminum, along with small amounts of other elements such as copper, magnesium, or zinc.

Overall, the type of aluminum alloy used depends on the specific application and desired properties, with each type of alloy offering unique advantages and disadvantages.

-

3.Properties of Aluminum Alloys

Aluminum alloys are known for their unique combination of properties, which can be tailored to specific applications by adjusting the alloy composition, microstructure, and processing methods. The key properties of aluminum alloys include:

3.1 Mechanical Properties

The mechanical properties of aluminum alloys include strength, ductility, toughness, and fatigue resistance. The strength of an aluminum alloy is primarily dependent on the alloy composition and processing method, with heat-treatable alloys exhibiting the highest strength. Ductility and toughness are also important mechanical properties, as they determine the ability of the alloy to deform and absorb energy without fracturing. Fatigue resistance refers to the ability of the alloy to withstand cyclic loading without cracking.

3.2 Physical Properties

The physical properties of aluminum alloys include density, melting point, and coefficient of thermal expansion. The density of aluminum alloys is approximately one-third that of steel, making them highly lightweight. The melting point of aluminum alloys ranges from 570°C to 660°C, depending on the alloy composition. The coefficient of thermal expansion of aluminum alloys is relatively low, which makes them suitable for applications that require dimensional stability over a wide range of temperatures.

3.3 Corrosion Resistance

Aluminum alloys are highly resistant to corrosion due to the formation of a protective oxide layer on the surface of the metal. This oxide layer acts as a barrier, preventing further oxidation and corrosion. However, the corrosion resistance of aluminum alloys can be affected by the alloy composition, processing method, and environmental factors.

3.4 Thermal Conductivity

Aluminum alloys are excellent thermal conductors, with thermal conductivity ranging from 120 to 210 W/mK, depending on the alloy composition. This makes them well-suited for applications that require efficient heat transfer, such as heat exchangers, engine blocks, and electronic components.

3.5 Electrical Conductivity

Aluminum alloys are also excellent electrical conductors, with electrical conductivity ranging from 30 to 70% of the International Annealed Copper Standard (IACS). This makes them well-suited for applications that require electrical conductivity, such as electrical conductors and electronic components.

Overall, the properties of aluminum alloys make them highly versatile and well-suited for a wide range of applications across various industries.

-

4.Applications of Aluminum Alloys

Aluminum alloys have found widespread use in various industries due to their unique combination of properties. Some of the key applications of aluminum alloys include:

4.1 Aerospace Industry

Aluminum alloys are extensively used in the aerospace industry due to their lightweight, high strength, and excellent corrosion resistance. They are used in the manufacture of aircraft structures, wings, fuselage, and engine components. Aluminum alloys are also used in the manufacture of spacecraft, satellites, and other space vehicles.

4.2 Automotive Industry

Aluminum alloys are increasingly being used in the automotive industry due to their lightweight, high strength, and corrosion resistance. They are used in the manufacture of engine blocks, wheels, suspension components, and body panels. The use of aluminum alloys in the automotive industry has led to significant improvements in fuel efficiency and reduced emissions.

4.3 Construction Industry

Aluminum alloys are used in the construction industry due to their lightweight, durability, and corrosion resistance. They are used in the manufacture of windows, doors, roofing, siding, and other structural components. Aluminum alloys are also used in the construction of bridges and other infrastructure projects.

4.4 Packaging Industry

Aluminum alloys are used in the packaging industry due to their excellent barrier properties, which protect the contents from light, moisture, and oxygen. They are used in the manufacture of beverage cans, food containers, and other packaging materials. Aluminum alloys are also recyclable, making them an environmentally-friendly choice for packaging.

4.5 Electrical Industry

Aluminum alloys are used in the electrical industry due to their excellent electrical conductivity and corrosion resistance. They are used in the manufacture of electrical conductors, power transmission lines, and other electrical components. Aluminum alloys are also used in the manufacture of electronic components, such as heat sinks and circuit boards.

Overall, the wide range of applications of aluminum alloys highlights their versatility and usefulness across various industries.

-

5.Advancements in Aluminum Alloy Technology

Advancements in aluminum alloy technology have led to the development of new alloys with improved properties and performance. Some of the key advancements in aluminum alloy technology include:

5.1 Microstructure Control

Microstructure control refers to the ability to control the size and distribution of the different phases in an aluminum alloy. This can be achieved through various processing techniques, such as heat treatment, deformation, and alloying. By controlling the microstructure of an aluminum alloy, it is possible to improve its mechanical properties, such as strength, toughness, and ductility.

5.2 Alloy Design and Development

Alloy design and development involve the creation of new aluminum alloys with specific properties for different applications. This is achieved through a combination of computational modeling, experimental testing, and material characterization. The goal is to develop alloys with improved properties, such as higher strength, better corrosion resistance, and increased formability.

5.3 Surface Treatment and Coatings

Surface treatment and coatings are used to improve the performance and durability of aluminum alloys in different environments. This includes surface treatments, such as anodizing, which creates a protective oxide layer on the surface of the aluminum alloy. Coatings, such as paints and powders, can also be applied to aluminum alloys to improve their corrosion resistance, wear resistance, and aesthetic appearance.

Overall, advancements in aluminum alloy technology are driving innovation and improving the performance and versatility of these materials in different applications. As the demand for lightweight and durable materials continues to grow, the development of new and improved aluminum alloys will play a critical role in meeting the needs of various industries.

-

6.Aluminum Recycling and Sustainability

Aluminum recycling is an important aspect of sustainability in the manufacturing industry. Here are some key points to consider:

6.1 Benefits of Aluminum Recycling

Aluminum recycling offers several benefits, including:

- Energy savings: Recycling aluminum requires significantly less energy than producing new aluminum from raw materials. According to the Aluminum Association, recycling aluminum saves up to 95% of the energy required to produce primary aluminum.

- Resource conservation: Recycling aluminum reduces the need for mining and extraction of new bauxite ore, the primary raw material for aluminum production. This helps conserve natural resources and reduces environmental impact.

- Economic benefits: Aluminum recycling creates jobs and contributes to the economy by supporting a growing recycling industry.

- Reduced landfill waste: Aluminum is a highly recyclable material, and recycling it reduces the amount of waste sent to landfills.

6.2 Environmental Impact of Aluminum Production

Aluminum production has a significant environmental impact, particularly in terms of energy consumption and greenhouse gas emissions. The primary source of emissions in aluminum production is the electrolysis process used to extract aluminum from bauxite ore.

To mitigate the environmental impact of aluminum production, manufacturers are adopting sustainable practices such as using renewable energy sources, implementing energy-efficient technologies, and optimizing production processes.

6.3 Sustainable Manufacturing Practices

Sustainable manufacturing practices are essential for reducing the environmental impact of aluminum production and increasing the sustainability of the manufacturing industry as a whole. Some of these practices include:

- Using renewable energy sources: Manufacturers can reduce their carbon footprint by using renewable energy sources such as solar, wind, or hydroelectric power.

- Optimizing production processes: Manufacturers can reduce energy consumption and emissions by optimizing production processes, improving equipment efficiency, and reducing waste.

- Reducing water usage: Aluminum production requires significant amounts of water, so reducing water usage through conservation and recycling is essential.

Overall, aluminum recycling and sustainable manufacturing practices are critical for reducing the environmental impact of aluminum production and increasing the sustainability of the manufacturing industry.

-

7.Conclusion: The Future of Aluminum Alloys

In conclusion, the future of aluminum alloys is bright, with emerging applications and industries, advancements in manufacturing processes, and a trend towards sustainable and eco-friendly practices. Aluminum alloys are becoming increasingly popular in industries such as aerospace, automotive, and construction due to their unique properties of strength, corrosion resistance, and lightweight. Manufacturing processes are also evolving with the development of new techniques such as additive manufacturing and advanced casting methods. Moreover, sustainable and eco-friendly practices are becoming a priority in the aluminum industry, with companies aiming to improve their environmental footprint by reducing energy and resource consumption and implementing recycling programs. Overall, aluminum alloys are expected to have a significant role in shaping the future of various industries, with their versatility and sustainability making them an attractive choice for innovative applications.At the end,Aluminum alloy In CNC Machining,you can choose the V1 Machining.Because the V1 Machining Provide manufacturing process, metal, and plastic instructions to meet the specific requirements of your CNC machined parts.