Machines are tools and devices that can help people reduce the difficulty or save labor. Objects such as chopsticks, brooms and tweezers can be called machines. They are simple machines. Complex machinery is composed of two or more simple machines. These more complex machines are usually called machines. From the point of view of structure and motion, there is no difference between mechanism and machine, which is generally called machinery.

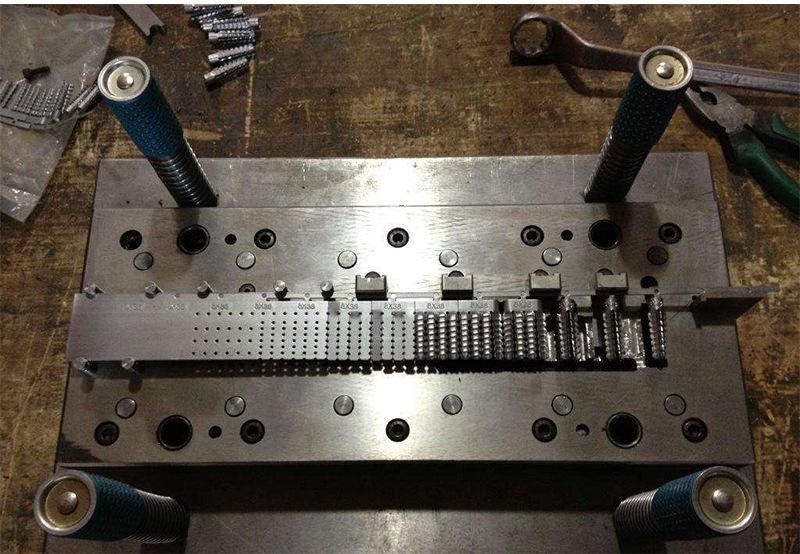

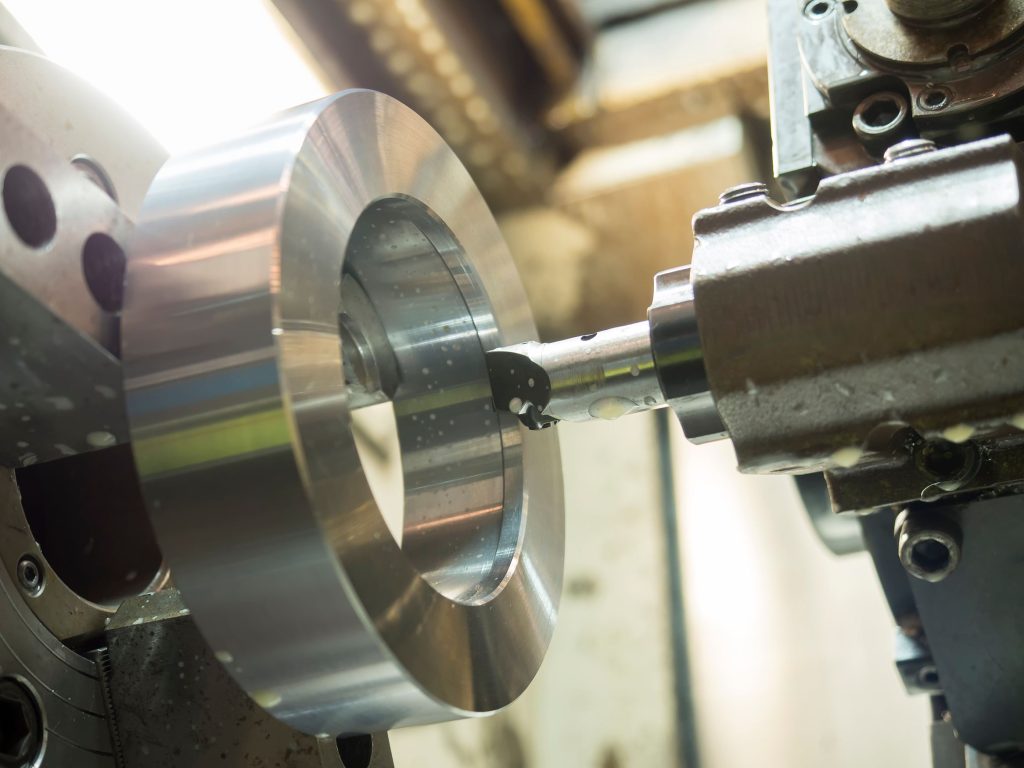

China machining shop is a factory mainly producing mechanical products, specifically including agricultural machinery manufacturing, industrial equipment manufacturing, transportation equipment manufacturing, construction and road building machinery manufacturing, production machinery manufacturing, metal products manufacturing, domestic machinery manufacturing, daily metal products repair, etc.

Mechanical parts are composed of several surfaces. To study the relative relationship between parts' surfaces, a datum must be determined. The datum is the point, line, and plane on the part used to determine the position of other points, lines, and surfaces. According to the different functions of the benchmark, the benchmark can be divided into two categories: design benchmark and process benchmark.

classification

Design datum: the datum used to determine the position of other points, lines and surfaces on the part drawing is called design datum.

Process datum: the datum used in the processing and assembly of parts, called process datum. According to different purposes, the process datum can be divided into assembly datum, measurement datum and positioning .

Datum

(1) Assembly datum: the datum used to determine the position of parts in components or products during assembly, called assembly datum.

(2) Measuring datum: the datum used to check the size and position of the machined surface, called measuring datum.

(3) Positioning datum: the datum used for workpiece positioning during machining, called positioning datum. For the surface used as the positioning datum, only the unfinished blank surface can be selected in the first process. This positioning surface is called the rough datum. The machined surface can be used as the positioning reference in the subsequent processes, and this positioning surface is called the precision reference.

Steps

(1) Analyze and research the assembly drawing and part drawing of the product

(2) Determine blank

(3) Draw up the process route and select the positioning base plane

(4) Determine the equipment used in each process

(5) Determine the tools, fixtures, measuring tools and auxiliary tools used in each process

(6) Determine the technical requirements and inspection methods of main processes

(7) Determine the machining allowance of each process, and calculate the process size and tolerance

(8) Determine cutting parameters

(9) Determine man hour quota

Design principles:

(1) The process procedures designed shall ensure the processing quality of machine parts (or the assembly quality of the machine) and meet the technical requirements specified in the design drawings.

(2) The production rate of the process should be high, so that the products can be put on the market as soon as possible.

(3) Try to reduce manufacturing costs

(4) Pay attention to reducing the labor intensity of workers and ensuring production safety.

Development status of China machining shop

With the rapid development of modern machining and machining technology, many advanced machining technology methods emerge slowly, such as micro machining technology, rapid prototyping technology, precision ultra precision machining technology, etc.