We all know that the high precision of CNC hand board machining and the ability to accurately control the quality of the product, coupled with the high production efficiency, makes it a mainstream hand board machining solution.

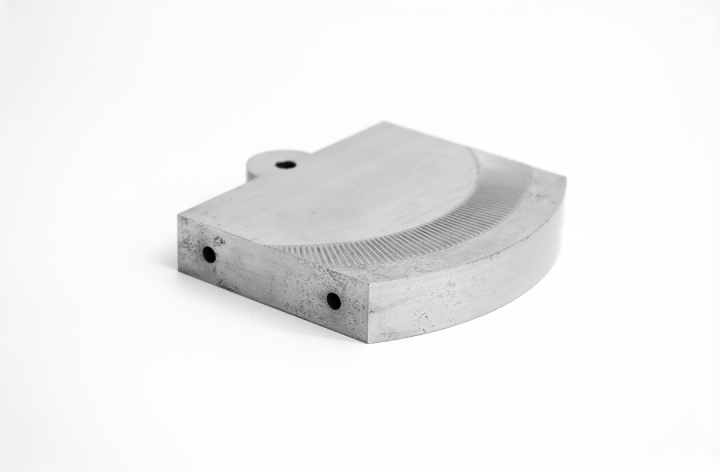

CNC hand board processing accuracy is indeed very high, the processing tolerance of plastic parts is generally within 100mm ± 0.15mm, metal parts within 100mm ± 0.08mm, we can see that it still has accuracy differences.

Then today we will analyze together, in the end, what is the reason for the existence of CNC tolerances?

- Dimensional accuracy

The degree to which the actual dimensions of the machined part correspond to the centre of the tolerance zone of the part dimensions. Dimensional accuracy is controlled by dimensional tolerances.

The dimensional tolerance is the amount of variation allowed in the dimensions of the part in the cutting process.

In the case of identical basic dimensions, the smaller the dimensional tolerance, the higher the dimensional accuracy.

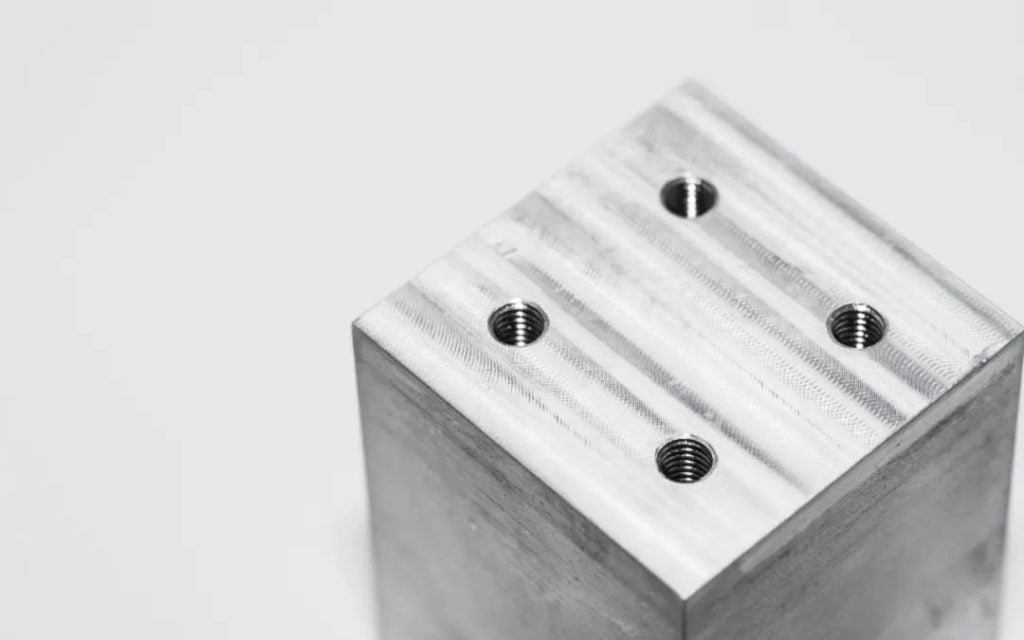

- Shape accuracy

Shape accuracy refers to the degree to which the actual geometry of the machined part surface conforms to the ideal geometry.

Shape accuracy is judged by straightness, flatness, roundness, cylindricity, line profile and other 6 items.

Shape accuracy is controlled by shape tolerance, each shape tolerance, except roundness, cylindricity is divided into 13 accuracy levels, the rest are divided into 12 accuracy levels. 1 level is the highest, 12 level is the lowest.

- Position accuracy

This refers to the difference in actual positional accuracy between the relevant surfaces of the machined part.

The items for assessing positional accuracy are parallelism, perpendicularity, inclination, coaxiality, symmetry, position, circular runout and full runout.

The positional accuracy is controlled by positional tolerances, which are also divided into 12 accuracy classes for each item.

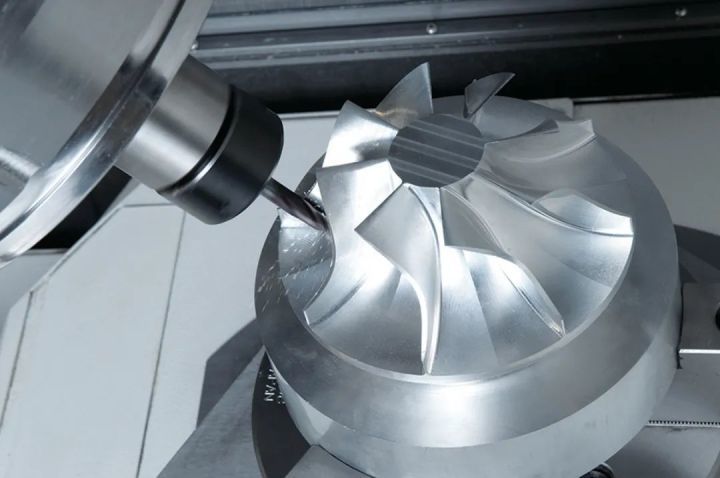

- Tools

The knives used in machining machines are generally tungsten steel knives, which generally wear out after a few uses, so that there are also errors in the knives.

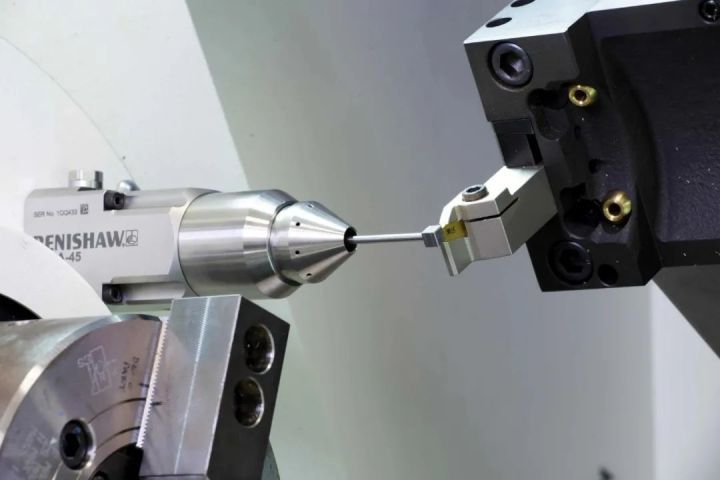

- Manual tool setting

If there is a tool setting instrument, there will be no problem in tool setting. But many small hand board factory, in order to save costs, in the choice of machine will choose no tool setting instrument, only manual knife, so the personnel and tolerances.

In order to ensure the accuracy of the hand board model, the CNC hand board processing equipment installed on top of the tool setting instrument, not only can be accurate to the knife, but also greatly improve the efficiency.

In addition to the above 5 factors that affect the accuracy of the CNC handpiece, the machining accuracy can also be affected by the need to turn the part over, for example.

All of these factors can lead to differences in the accuracy of the final model, so it is important to start with each aspect of machining accuracy to produce the best possible model.