Anodizing Process Service

Pure aluminum forms a 1 to 10 nm thick oxide layer due to the reaction from oxygen. This oxide layer prevents aluminum from corrosion and wear. The higher the thickness of the oxide layer, the more will be the corrosion resistance.

Anodizing Process increases oxide layer thickness to improve aluminum and other non-ferrous alloy corrosion resistance.

Anodizing is an electrochemical conversion process for producing variable oxide layers thickness on aluminum and other non-ferrous metals such as magnesium and titanium. Oxide layer thickness can vary from 1 to 80µm.

How to Anodize Aluminum?

The part is submerged in an electrolytic solution (acidic) bath with a cathode during aluminum anodizing. During anodizing, the metal Part works as an anode.

When a current is passed through an electrolytic solution, the cathode releases the hydrogen and oxygen forms on the anode surface. In this way, the metal oxide film forms on the anode surface. Experts recommend performing machining drilling, and welding operations before anodizing.

Advantages of Anodizing

Anodizing Process has the following advantages compared to other metal finishing operations.

- Improved corrosion and wear resistance.

- Good aesthetic

- Can achieve a variety of colors.

- Clear finish options are also available.

- Low cost compared to powder coating.

- Extremely durable, hard, abrasion-resistant, and long-lasting.

- Recyclable.

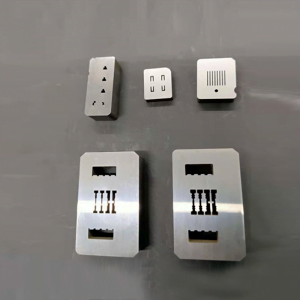

Products

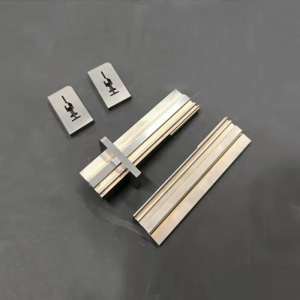

.01

Mechanical Parts Machining's Capacity

For processing orders of mechanical part, all are produced and processed by “Mechanical Parts Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

72

Production equipments

49

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.02

Precision Mold Parts Machining's Capacity

For processing orders of precision mold parts, all are produced and processed by “Precision Mould Parts Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

66

Production equipments

24

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

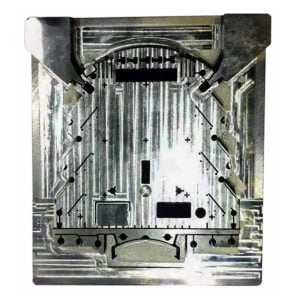

.03

Large Parts Machining's Capacity

For the processing and customized orders of Large parts, the “Large CNC Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

59

Production equipments

154

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

CNC Manufacturing Materials

Choose the right materials for your manufacturing needs from prototype to production

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries:

Custom Anodizing Process Services

If you need any metal and plastic cnc machining and custom Anodizing Process surface treatment services