Know about Precision Mold Parts

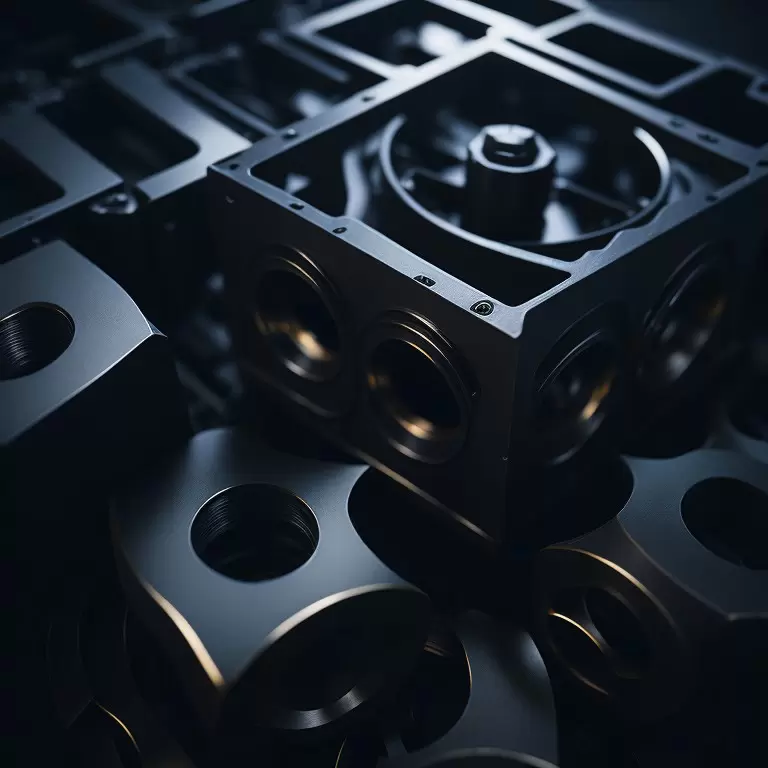

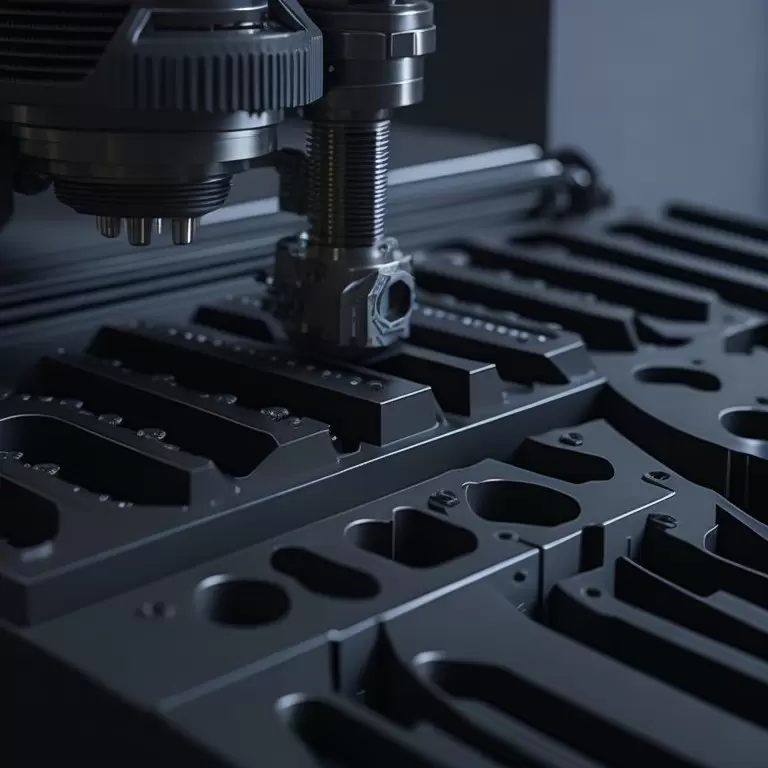

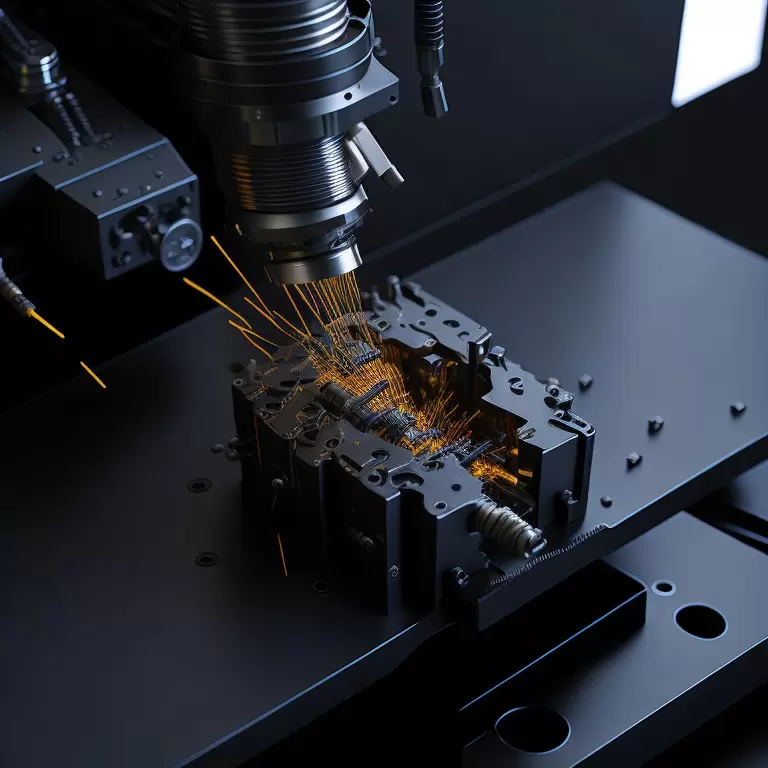

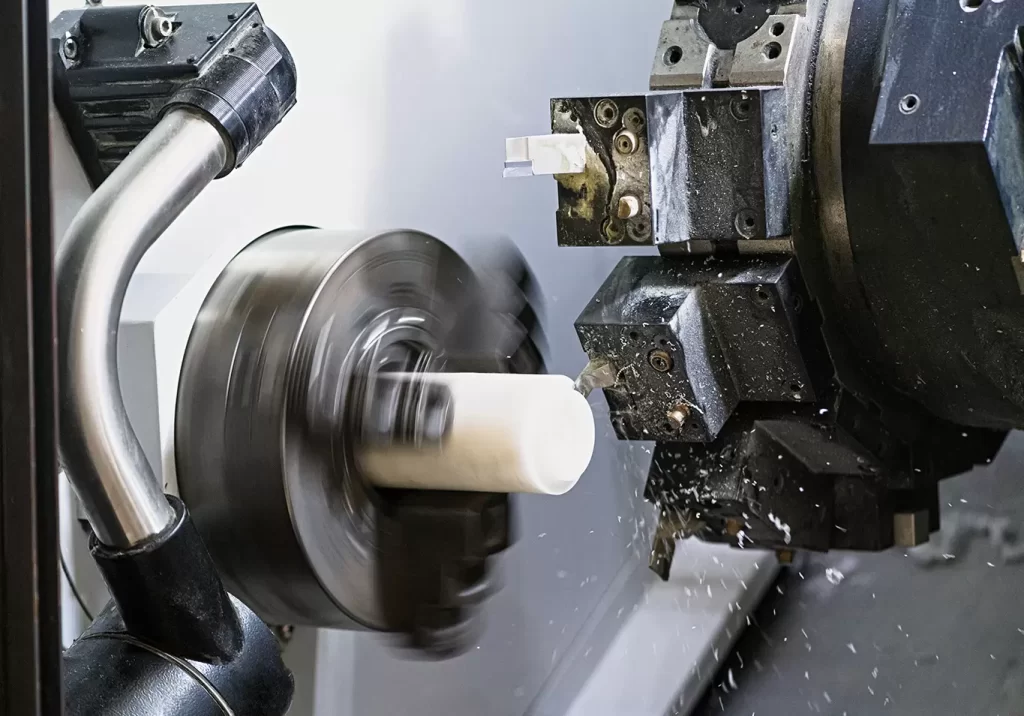

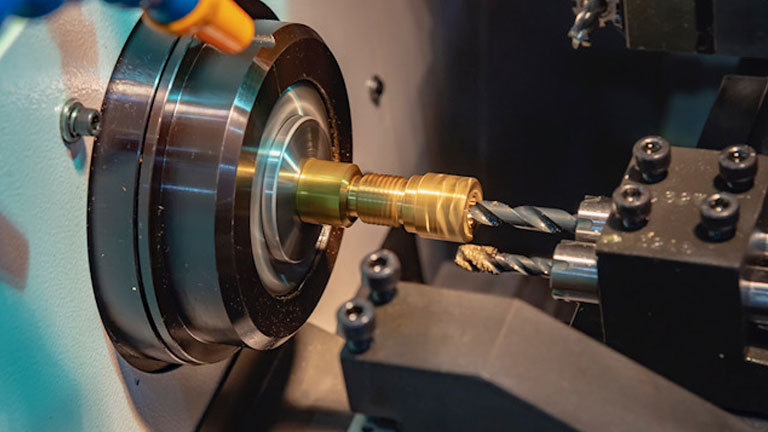

Precision mold parts are unique components that are specifically designed to fit into a mold and help accurately shape and form various materials used in manufacturing. These parts allow manufacturers to create products with high precision, accuracy, and consistency.

Know about Precision Mold Parts Read More »