In modern industry, machining is a measure of a country's manufacturing level, and precision machining and ultra-fine precision technology, but also represents the highest level of machining, whether the mastery of these technologies represents the level of industrial manufacturing of the entire country.

We all know that in the level of machining Germany should be the most powerful, this is because Germany has the most advanced machine tools, and very good and rigorous technical workers, in fact, in addition to Germany, Japan's precision machining is also not to be underestimated, to see what level of Japanese finishing technology has actually reached.

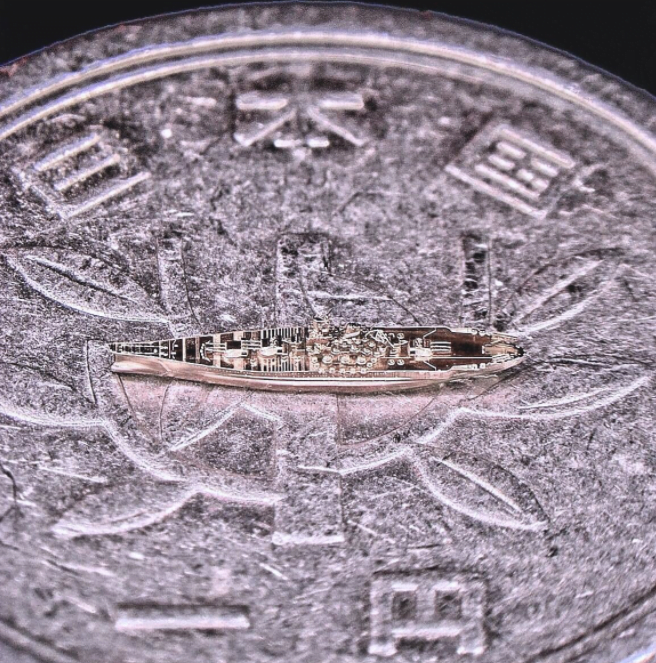

Microscope to see the battleship

Usually 0.2 mm this size, we can hardly see with the naked eye, so it is very difficult to manufacture a single product smaller than this size, not to mention that the product is a combination of many parts.

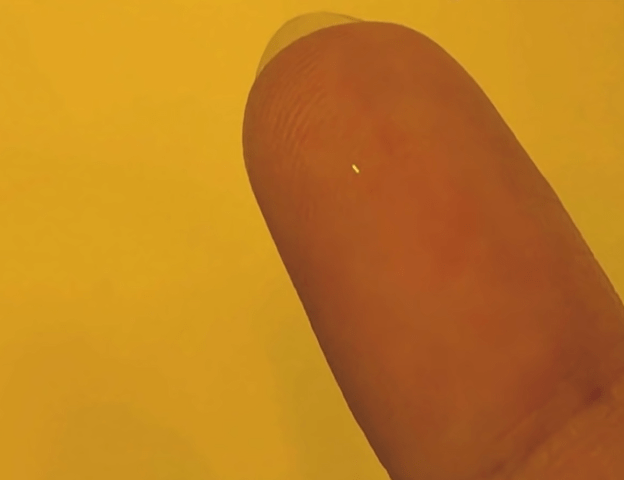

There is a Japanese precision machining factory, manufactured only hair diameter Yamato battleship model, placed in other places will not even notice it, or even find, placed on the finger is a shiny white dot.

To see it clearly only with the help of a microscope, zoom in, the surface is a little jagged, but do not know what it is yet, and then zoom in, the real face of the white dot is the ship.

And this model is not only the hull, even the ship's cannons, the deck is equipped with other facilities, very fine workmanship.

The battleship model is an ultra-small model replicated to one 520,000th of the real thing, and all parts are made using new nano-3D printing and ultra-microfabrication.

The entire battleship model is 0.5 mm in length, and the ship's several iconic main guns are 0.003 mm.

Such small parts in the assembly also need to use microfabrication manual hand operation, the need to use the electron microscope, assembly while looking at the microscope screen, while operating the knob to rely on the robot arm can complete the assembly of fine parts.

This hair-like model once exhibited let everyone marvel at the ability to create such a small model, requiring very high parts processing technology and craftsmanship.

There are many more precision machining like this perverted level, such as the following.

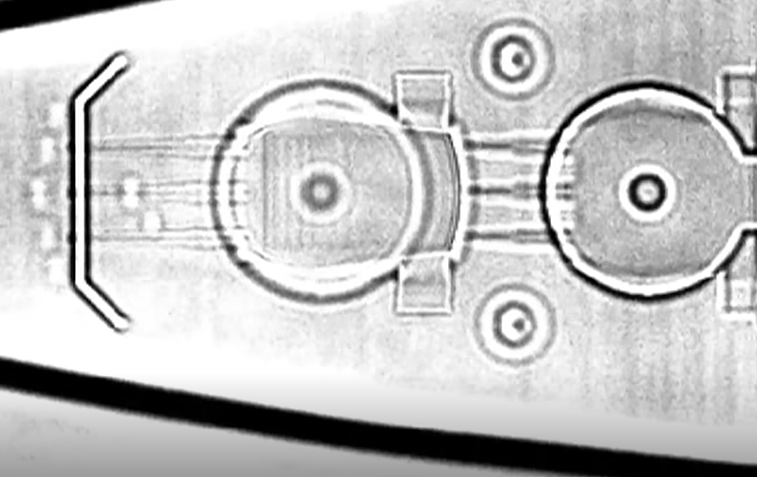

Miniature fingertip gyroscope

We basically hand played gyroscope as a child, when the gyroscope are very simple, and are also made by their own hands, now people are starting to play more advanced fingertip gyroscope.

Japan, a very small precision machining factory, has made a world's smallest fingertip gyro Smallest fldget spinner, and was certified by the Guinness Book of Records, and issued a certificate.

How small is it? It is only 5.09 mm in diameter, with a single ball bearing outer diameter size of 1.5 mm (which is also the smallest mass-produced ball bearing in the world), a thickness of only 0.8 mm, and a ball diameter of 0.1 mm in the bearing.

Although the size of this fingertip gyro is too small, but it is not a craft that can not play, will be placed on a certain fulcrum, the same can quickly turn up, with the same function as the ordinary fingertip gyro.

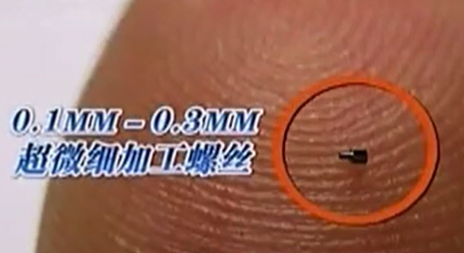

Can produce such precision products is not a big company, but a processing plant called Yuki precision manufacturing, this factory only 40 people, even can be called processing small workshops, but has been established 50 years of history, and its research and development and production out, such as only 0.1 ~ 0.3 mm ultra-fine screws and other products in the space shuttle, artificial satellite widely used.

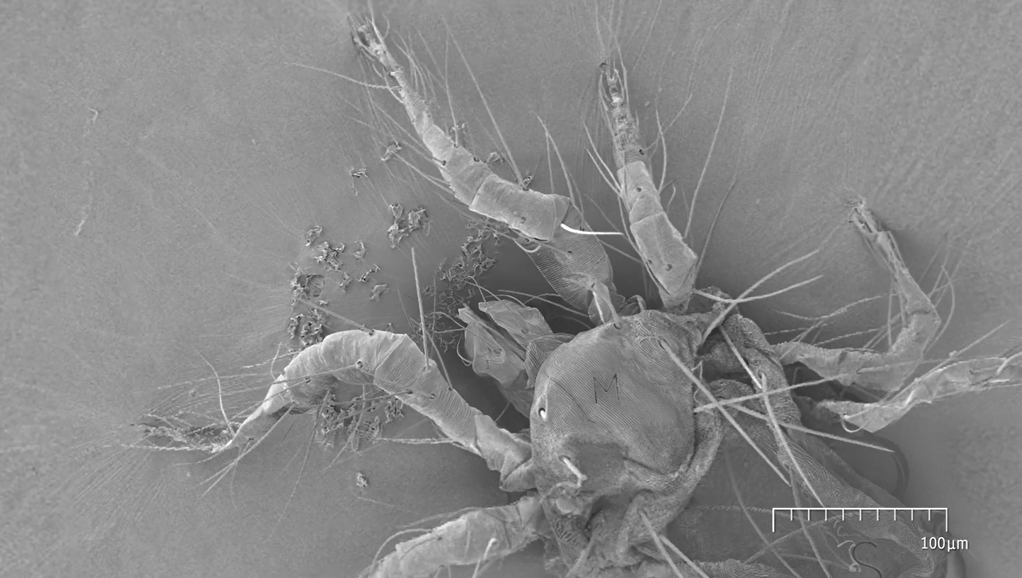

Engraving on mites

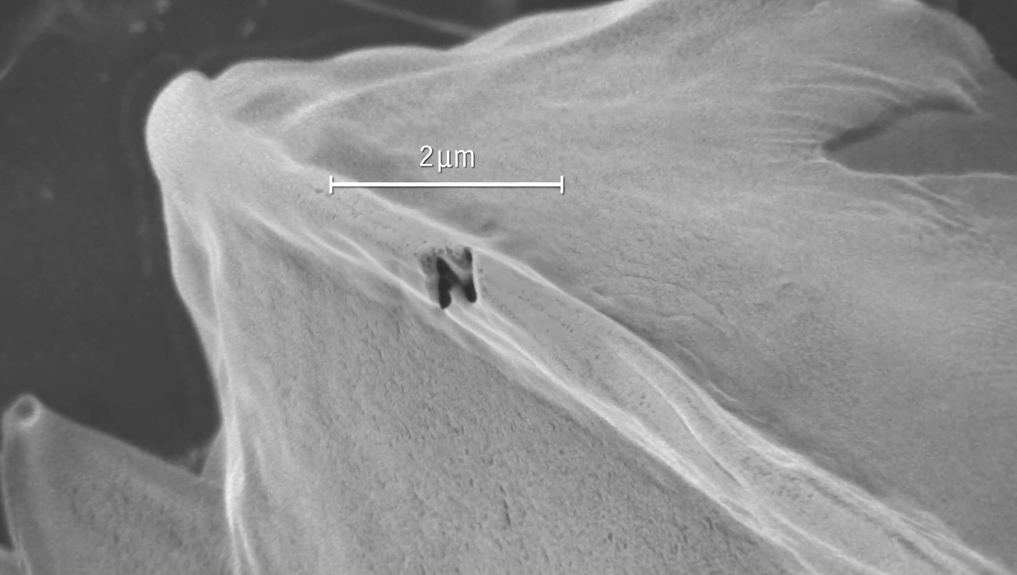

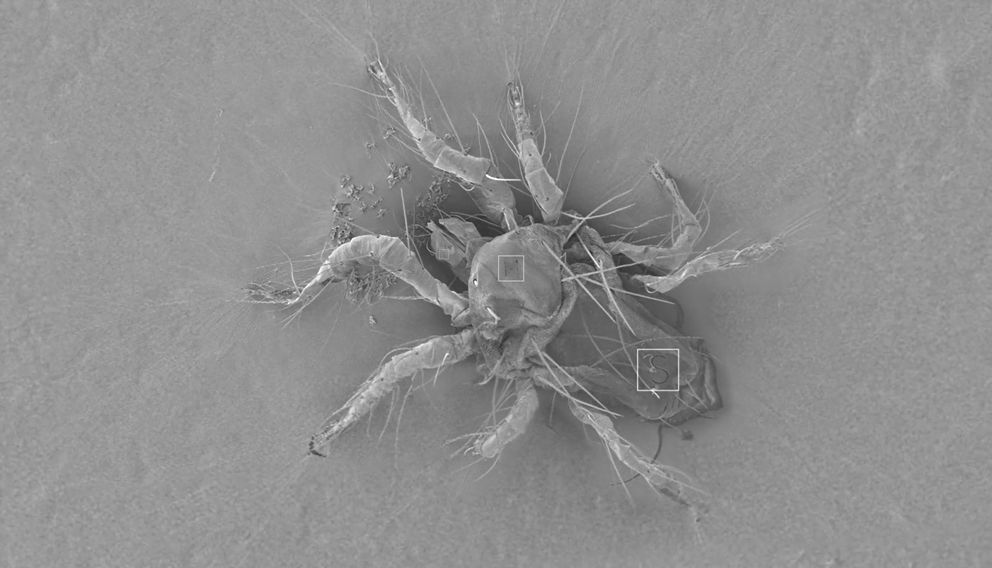

We can't see what mites look like with the naked eye, but a Japanese materials research institute (NIMS) has succeeded in using ultra-fine processing technology to engrave letters on mites, achieving nano-level processing.

By looking under the electron microscope, the mite's mouth was engraved with an "N" character, which was less than 2 microns (0.002 mm) in length, a character smaller than E. coli.

In the tiny mite body there are multiple places are engraved with words, to be able to see will need to slowly look, which shows how small the font is.

This ultra-fine structure technology can be used for the development of electronic components and the processing of those smaller materials, such as nanoscale materials.

The world's smallest surgical needle

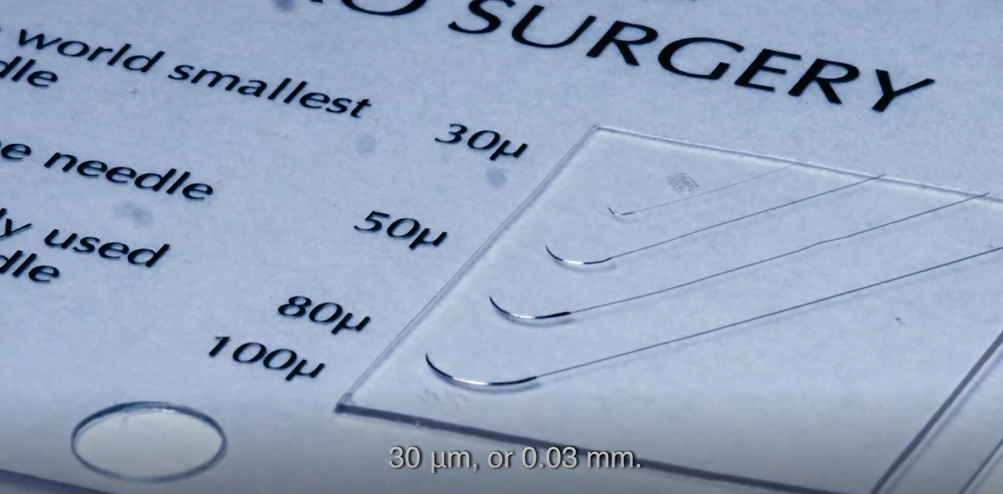

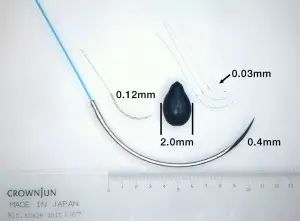

Among many medical devices, surgical needles seem to be one of the simpler ones, but it is not easy to make them smaller. A Japanese medical device manufacturer, has developed the world's smallest surgical needle.

How thin is it? It is only 0.03 mm in diameter and 0.8 mm long, while the thread used to close the wound is only 0.012 mm in diameter.

This ultra-small surgical needle used is a special stainless steel material, because it is too fine, all the processing process cutting, stretching, grinding tip and other each process is very difficult.

If the surgical needle is punched with a lead hole, the traditional punching method will not work, and the laser punching will easily melt the metal directly.

Such a surgical needle is invisible to the naked eye, which makes it possible to perform microsurgery previously thought impossible, such as the suturing of blood vessels, lymph vessels and nerves below 0.5 mm.

We are amazed by these ultra-fine precision technologies of Japan, which can persist and innovate for decades in some seemingly insignificant fields, and eventually make world-leading products and technologies.