V1 Passivation Process Service

V1 Machining employs many different methods of passivation, including:

- Tank Immersion – Usually done at an V1 Machining site and is advantageous for treating all the fabrication surfaces at the same time for uniformity of finish and optimum corrosion resistance.

- Circulation – Chemical solution is circulated through a system of pipework and is particularly recommended for piping that will carry corrosive liquids.

- Spray Application – Can be done at V1 Machining or at a customer site and advantageous for on-site treatment but proper acid disposal and safety procedures are essential.

- Gel Application – Manual treatment can be accomplished by brushing on pastes or gels to the surface. It is useful for spot treatment of welds and other intricate areas that require manual detail.

Why passivate stainless steel?

Passivation is a post-fabrication best practice for newly-machined stainless steel parts and components. Benefits include:

- Chemical film barrier against rust

- Extended life of the product

- Removal of contamination from product surface

- Reduced need for maintenance.

How does passivation work?

Stainless steel is an iron-based alloy, typically composed of iron, nickel and chromium. Stainless steel derives its corrosion-resistant properties from the chromium content. Chromium, when exposed to oxygen (air), forms a thin film of chromium oxide that covers the stainless steel surface and protects the underlying iron from rusting. The purpose of passivation is to augment and optimize formation of the chromium oxide layer.

The resulting passive layer provides a chemically non-reactive surface that protects against rust.

Products

.01

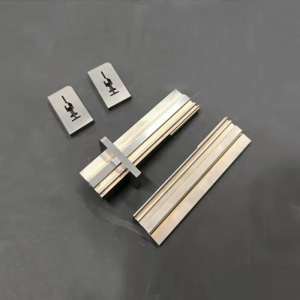

Mechanical Parts Machining's Capacity

For processing orders of mechanical part, all are produced and processed by “Mechanical Parts Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

72

Production equipments

49

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.02

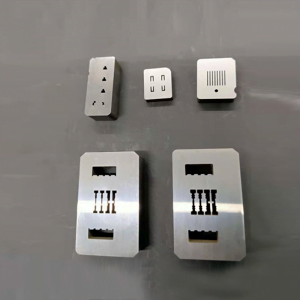

Precision Mold Parts Machining's Capacity

For processing orders of precision mold parts, all are produced and processed by “Precision Mould Parts Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

66

Production equipments

24

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.03

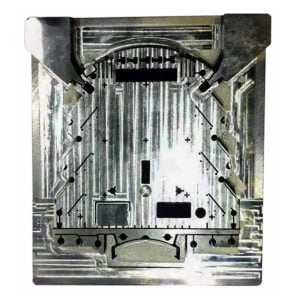

Large Parts Machining's Capacity

For the processing and customized orders of Large parts, the “Large CNC Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

59

Production equipments

154

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

CNC Manufacturing Materials

Choose the right materials for your manufacturing needs from prototype to production

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries:

Custom Passivation Process Services

If you need any metal and plastic cnc machining and custom Passivation Process surface treatment services