Three-axis robots

Most of the three-axis manipulators only have a single arm, only special orders have double arms. But all are double-cut type, and the application of the multiplier mechanism, the speed of the arm faster, shorter take out time. The lead arm and pick arm are made of high strength aluminum, with precision linear slide, light weight, good steel, low friction, which can make the robot more durable.

It has the following advantages

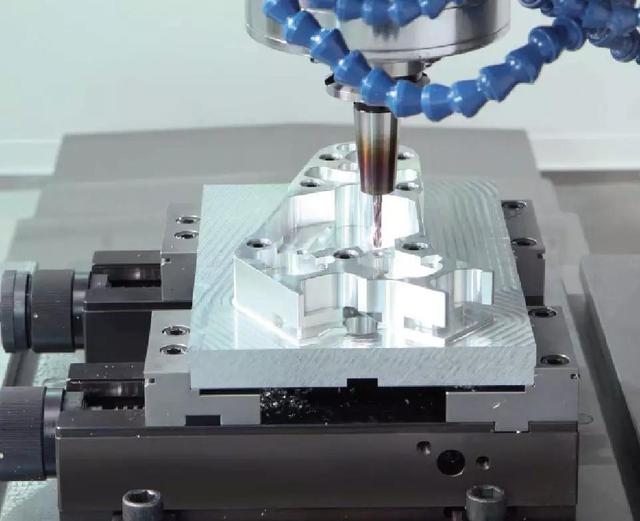

(1)improve the efficiency of work: three-axis injection molding machine robot is an intelligent mechanical operating equipment and has a variety of action operating instructions, can imitate the manual operation of a variety of actions to work, work with high accuracy and can complete a large workload, especially the short cycle of work tasks can improve production as scheduled.

(2) save labor costs: three-axis injection molding machine robot is mainly for the effective reduction of manual work and the birth of the enterprise to use the robot to reduce the amount of manual work to save labor costs, and can also complete a variety of gravity labor and repetitive stacking operations.

(3) reduce the engineering accident: many mechanized work process there are certain risks, the operation of a careless will appear accidental phenomenon. The operation of the three-axis injection molding machine manipulator is set by program instructions and the operation of standardized action, and strong adaptability to different working environments, whether it is a lot of oil or high temperature or corrosive working environment can adapt.

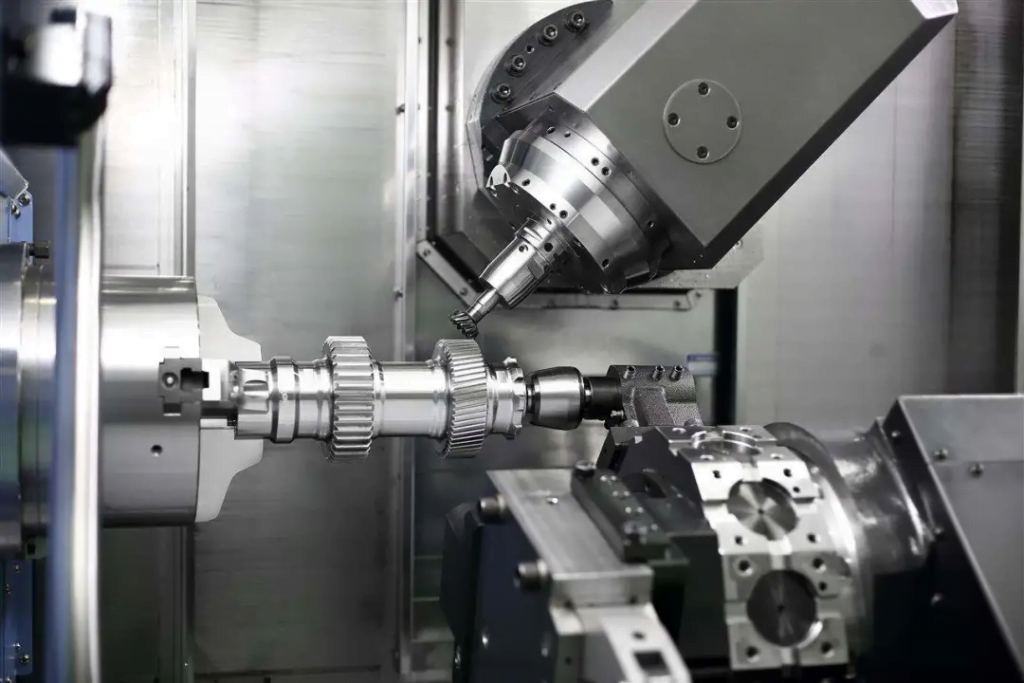

Five-axis robots

Compared to the three-axis robot, five-axis robot can be said to be a little more versatile. It has the same functions as the three-axis, and it is a full range of double-arm double-cut type. And the five-axis robot is a full servo robot. What is a "servo" robot?

Servo refers to a robot that is driven entirely by electricity. The three-axis is both pneumatic and electric, so the three-axis is also called servo robot, but not "full". The full range of five-axis injection molding robot is fully servo, because the five-axis injection molding robot is purely electric, the horsepower is also sufficient compared to the three-axis.

(1) In the normal production of injection molding work by five-axis servo robot to remove the product, injection molding machine cycle fixed, the stability of the finished product is excellent, so that the quality is guaranteed.

(2) five-axis servo manipulator is equipped with a safety protection system, the maximum extent to avoid the risk of accidental injury to employees, so that the operator can use peace of mind, and steadily advance the factory tasks.

(3) five-axis servo manipulator to implement a mechanism of one person, a dedicated person responsible for more in place. Each staff member can have a comprehensive understanding of the machine they are responsible for, timely inspection and maintenance, familiar with the machine's operating conditions and machine output, to achieve the perfect man-machine cooperation system, so that the five-axis servo robot becomes a good partner for factory operation.

Of course the five-axis servo robot also has its drawbacks, precisely because it is completely electric powered if a sudden power failure, then it is also possible to cause the work to stop, which will lead to its production speed is too slow. This is one of the other disadvantages.